A double layer packing box roll forming machine is a specialized piece of equipment designed to efficiently and accurately produce double layer packing boxes. These machines are commonly used in manufacturing facilities that require high-volume production of packing boxes for various purposes. By utilizing advanced technologies and precision engineering, these machines are able to streamline the production process and improve overall efficiency.

Benefits of Using a Double Layer Packing Box Roll Forming Machine

There are several key benefits to using a double layer packing box roll forming machine. These machines are able to produce packing boxes at a rapid pace, reducing production time and increasing output. Additionally, they are versatile and can be easily adjusted to accommodate different box sizes and specifications. This flexibility makes them ideal for facilities that require a range of packing box options.

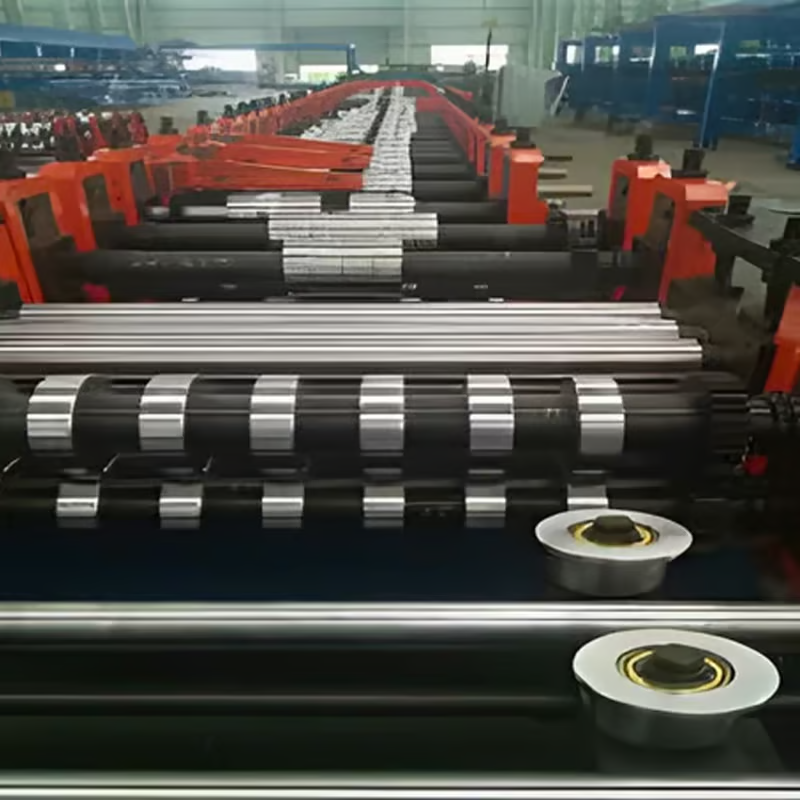

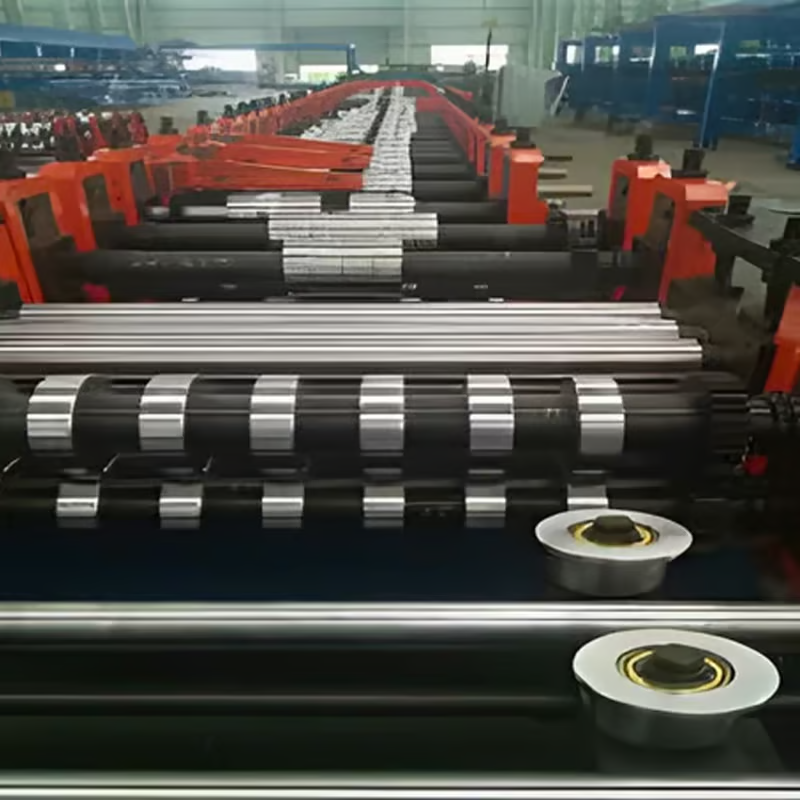

How a Double Layer Packing Box Roll Forming Machine Works

The operation of a double layer packing box roll forming machine is relatively straightforward. Sheets of material are fed into the machine, where they are then formed into the desired box shapes using a series of rollers and bending mechanisms. These machines are highly automated, with computerized controls that ensure precise and consistent box production.

Choosing the Right Double Layer Packing Box Roll Forming Machine

When selecting a double layer packing box roll forming machine, it is important to consider your specific production needs and requirements. Factors such as box size, material thickness, and production volume should all be taken into account. Additionally, it is advisable to choose a machine from a reputable manufacturer with a track record of producing high-quality equipment.

Maintenance and Servicing of Double Layer Packing Box Roll Forming Machines

Like any piece of machinery, double layer packing box roll forming machines require regular maintenance and servicing to ensure optimal performance. This may include routine cleaning, lubrication, and inspection of key components. It is also important to address any issues or malfunctions promptly to prevent costly downtime.

Industry Applications of Double Layer Packing Box Roll Forming Machines

Double layer packing box roll forming machines are commonly used in a variety of industries, including packaging, manufacturing, and logistics. These machines are essential for producing packing boxes for shipping, storage, and display purposes. Their efficiency and accuracy make them a valuable asset for businesses seeking to streamline their production processes.

Future Trends in Double Layer Packing Box Roll Forming Technology

As technology continues to advance, we can expect to see further innovations in double layer packing box roll forming machines. These advancements may include enhanced automation, integration with other production systems, and improved efficiency and speed. Manufacturers are constantly looking for ways to improve their equipment and stay ahead of the competition.

Environmental Considerations in Double Layer Packing Box Production

Sustainability is a growing concern in the packaging industry, and manufacturers are increasingly looking for ways to reduce their environmental impact. Double layer packing box roll forming machines can play a role in this effort by optimizing material usage and minimizing waste. By producing boxes more efficiently, businesses can reduce their carbon footprint and contribute to a more sustainable future.

Training and Education for Double Layer Packing Box Roll Forming Machine Operators

To ensure smooth operation and maximum productivity, operators of double layer packing box roll forming machines should receive adequate training and education. This may include instruction on machine setup, operation, troubleshooting, and maintenance. Properly trained operators can help minimize errors and downtime, leading to increased efficiency and profitability.

Conclusion

Double layer packing box roll forming machines are essential tools for businesses that require high-volume production of packing boxes. By investing in quality equipment and implementing best practices for maintenance and operation, companies can enhance their production processes and stay competitive in the market. As technology continues to evolve, we can expect to see further advancements in double layer packing box roll forming technology, leading to greater efficiency and sustainability in the industry.

Quote Inquiry

Contact us!