Table of Contents

Introduction

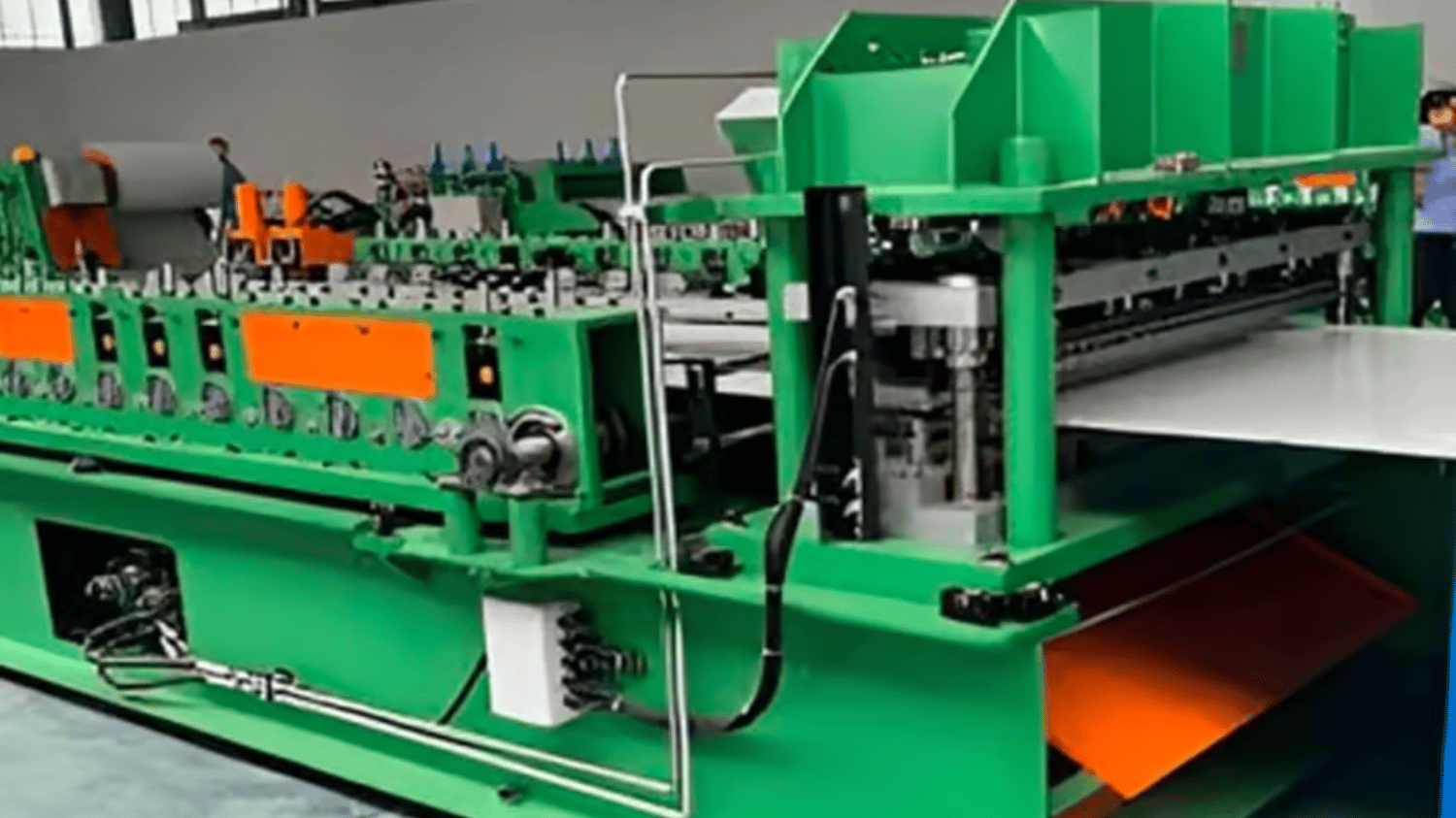

A Box plate roll forming machine is a high-precision machine designed to produce box-shaped metal plates. These machines are equipped with various rollers, which bend and shape the material into the desired shape and size. The process is continuous and can produce high volumes of box plates in a relatively short period. In this article, we will take an in-depth look at the box plate roll forming machine and its various aspects.

The Working Principle of a Box Plate Roll Forming Machine

The working principle of a box plate roll forming machine is based on the idea of continuous bending and shaping a metal strip to produce a box-shaped product. The machine is equipped with a set of rolls, each designed to exert a specific bending force on the material passing through it. The rollers are arranged in a specific sequence so that the final product is produced as desired. The process is controlled by a computer, which ensures that the rollers exert the correct force and that the final product meets the required specifications.

The Components of a Box Plate Roll Forming Machine

A box plate roll forming machine consists of various components that work together to produce the final product. These components include the material decoiler, which holds the metal strip, the rollers, the cutting system, and the control system. The material decoiler feeds the metal strip into the machine, and the rollers shape it into the desired shape. The cutting system cuts the final product to the required length. The control system regulates and monitors the entire process, ensuring that the final product meets the required specifications.

The Types of Box Plate Roll Forming Machines

There are different types of box plate roll forming machines, each designed for specific applications. Some of the most common types include the manual box plate roll forming machine, the hydraulic box plate roll forming machine, and the electric box plate roll forming machine. The manual machine is operated manually and is suitable for small-scale operations. The hydraulic machine is powered by hydraulics and is suitable for heavy-duty operations. The electric machine is powered by electricity and is ideal for automated operations.

The Advantages of a Box Plate Roll Forming Machine

The box plate roll forming machine offers various advantages, including:

- High precision: The machine can produce box plates to very precise specifications.

- High output: The machine can produce box plates in high volumes.

- High efficiency: The machine can produce box plates in a relatively short time.

- Low waste: The machine produces little waste material.

- Low labor cost: The machine requires minimal labor to operate.

The Applications of Box Plate Roll Forming Machines

Box plate roll forming machines are used in various industries, including:

- Construction: The boxes produced by the machine are used in the construction of buildings, bridges, and other structures.

- Automotive: The boxes produced by the machine are used in the manufacture of automotive parts.

- Shipping: The boxes produced by the machine are used in the packaging and shipping industry.

- Electronics: The boxes produced by the machine are used in the manufacture of electronic devices.

Factors to Consider When Choosing a Box Plate Roll Forming Machine

When choosing a box plate roll forming machine, several factors need to be considered, including:

- The type of material to be used

- The size of the box plates to be produced

- The required output

- The level of precision required

- The available space for the installation

The Maintenance of a Box Plate Roll Forming Machine

Proper maintenance is essential to ensure the longevity and optimal performance of the machine. Regular maintenance should include:

- Cleaning the machine after use

- Lubricating the machine parts

- Replacing worn-out parts

- Regular inspection of the machine

The Cost of a Box Plate Roll Forming Machine

The cost of a box plate roll forming machine depends on various factors, including the type, size, and specifications of the machine. Prices for manual machines can start from a few thousand dollars, while prices for hydraulic and electric machines can range from tens of thousands to hundreds of thousands of dollars.

Conclusion

The box plate roll forming machine is a versatile and invaluable tool in various industries. It offers high precision and efficiency and can produce box-shaped products in high volumes. When choosing a machine, it is essential to consider the factors discussed in this article to ensure optimal performance. Proper maintenance is also vital in ensuring the longevity of the machine.