Roof panel/wall panel/door panel roll forming machines are specialized industrial equipment designed to shape metal coils into specific profiles used in construction and manufacturing. These machines efficiently produce panels with consistent dimensions, enhancing the productivity and quality of building materials. Their advancement has revolutionized production processes, enabling rapid fabrication of structural components for roofs, walls, and doors.

Key Components and Working Principle

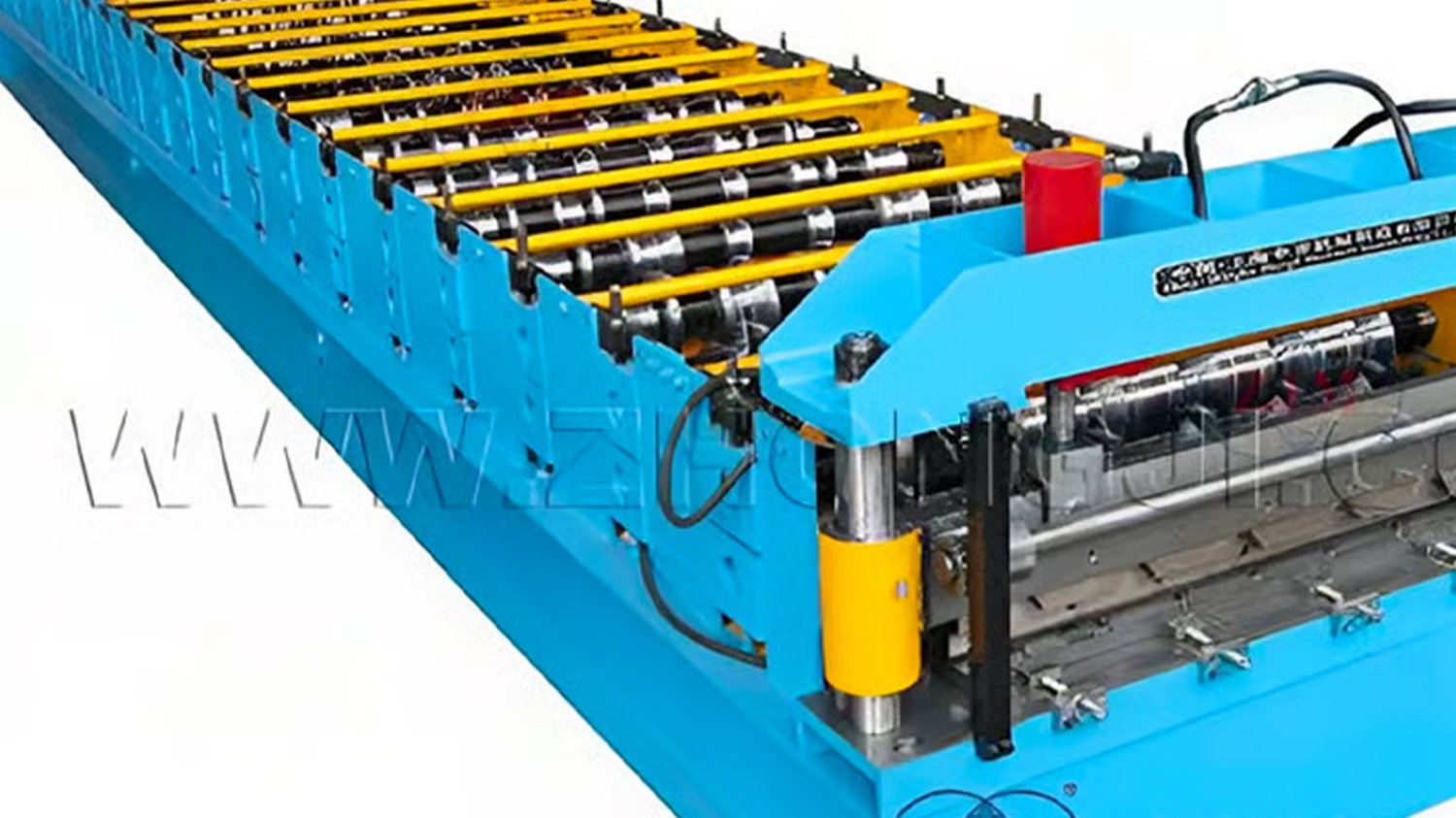

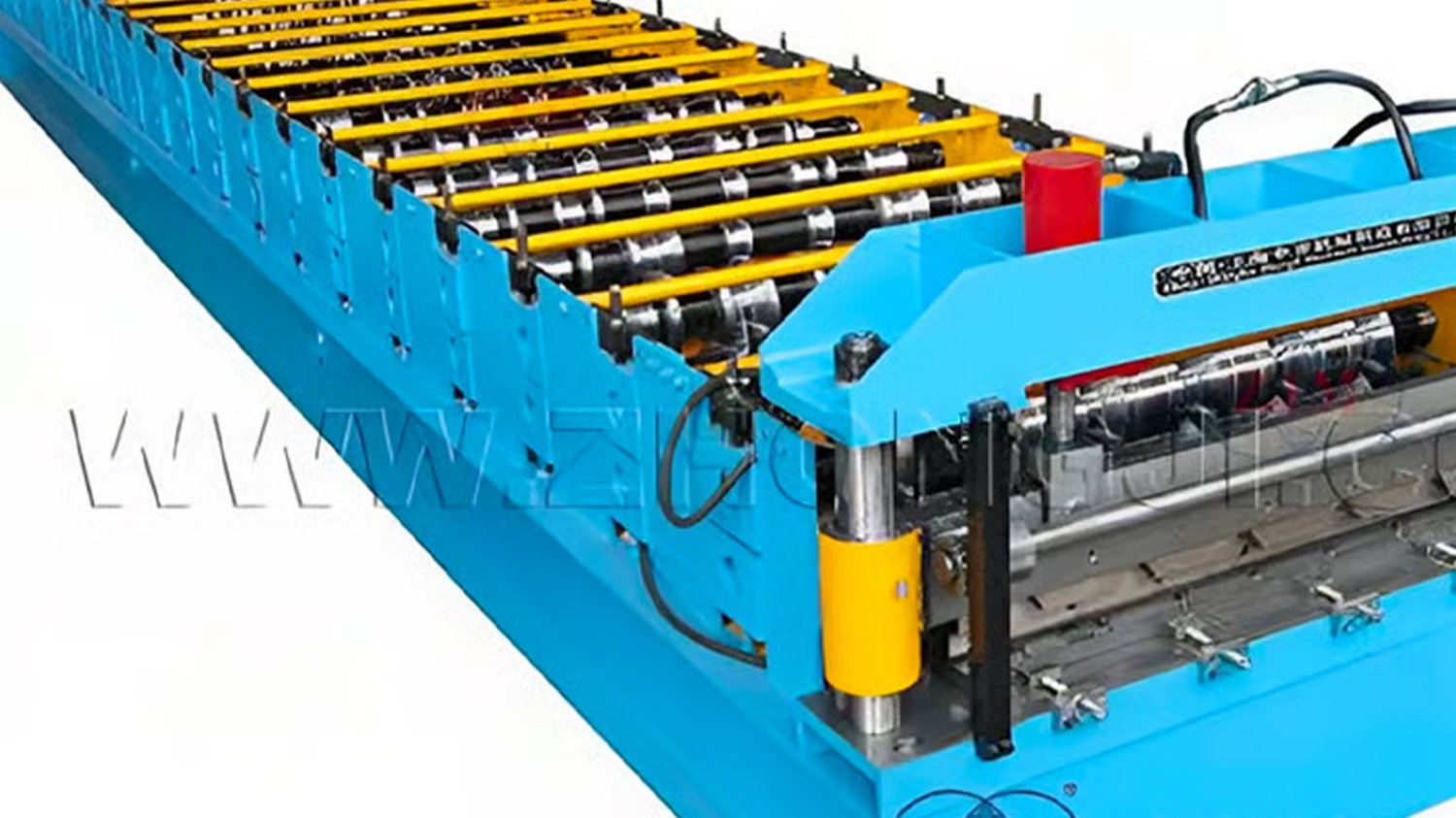

The core of a roof panel/wall panel/door panel roll forming machine lies in its series of roller dies that gradually bend metal strips into pre-set shapes. Raw metal coils feed into the machine, passing through multiple roller stations where incremental deformation takes place. The continuous roll forming process ensures precision while reducing material waste. Auxiliary systems like feeding mechanisms, punching units, and cutting devices complement the main operation for complete panel fabrication.

Material Compatibility and Versatility

Roll forming machines for roof panels, wall panels, and door panels are typically compatible with a range of metals including galvanized steel, aluminum, and stainless steel. This flexibility allows users to select materials based on application requirements such as durability, corrosion resistance, and weight. The versatility of these machines enables customization of panel thickness and profile shapes, catering to diverse architectural and industrial designs.

Customization and Design Flexibility

A significant advantage of roof panel/wall panel/door panel roll forming machines is their adaptability to various panel patterns and dimensions. Manufacturers can tailor panel width, rib height, and contour profiles to match specific construction needs. This customization ability supports innovative designs and structural requirements, allowing the production of aesthetically pleasing and functional panels for modern buildings.

Efficiency and Production Capacity

Roll forming technology dramatically increases production speed compared to traditional fabrication methods. Roof panel/wall panel/door panel roll forming machines can operate continuously, producing hundreds of meters of paneling per hour. This efficiency reduces lead times, allows for large-scale manufacturing, and lowers labor costs, making them indispensable in commercial construction and mass production settings.

Applications in Construction and Industry

Panels produced by these roll forming machines are widely used in residential, commercial, and industrial construction. Roof panels provide weatherproofing and structural integrity; wall panels contribute to insulation and facade aesthetics; door panels offer durability and security. Additionally, these panels find applications in warehouses, cold storage facilities, and modular buildings where rapid assembly and robustness are essential.

Automation and Control Systems

Modern roof panel/wall panel/door panel roll forming machines integrate advanced computerized control systems to enhance precision and operator safety. Programmable logic controllers (PLC) and human-machine interfaces (HMI) enable operators to set parameters, monitor real-time production data, and adjust operation speeds. Automation minimizes human error, ensures product consistency, and provides seamless integration with other production line equipment.

Maintenance and Operational Longevity

Proper maintenance is critical to sustain the performance of roll forming machines. Routine inspection of rollers, lubrication of moving parts, and timely replacement of wear components extend operational longevity. Machines designed with durable materials and modular components facilitate easier repairs and reduce downtime, ensuring continuous panel production without compromising quality.

Environmental Impact and Sustainability

Using roof panel/wall panel/door panel roll forming machines contributes to sustainable construction by optimizing material usage and reducing waste. The precision forming process minimizes scrap metal, and many machines support recycling of off-cuts. Moreover, metal panels produced are often recyclable at end-of-life, promoting circular economy principles within the building industry.

Future Trends and Technological Innovations

The roll forming industry is evolving with developments in smart manufacturing and Industry 4.0 integration. Emerging roof panel/wall panel/door panel roll forming machines incorporate IoT-enabled sensors for predictive maintenance and data-driven operations. Advances in materials science also introduce lightweight composites processed through roll forming, expanding possibilities for energy-efficient and high-performance panel solutions.

Quote Inquiry

contact us