Table of Contents

The Advantages and Uses of a 1 + 1 Continuous Laminating Machine

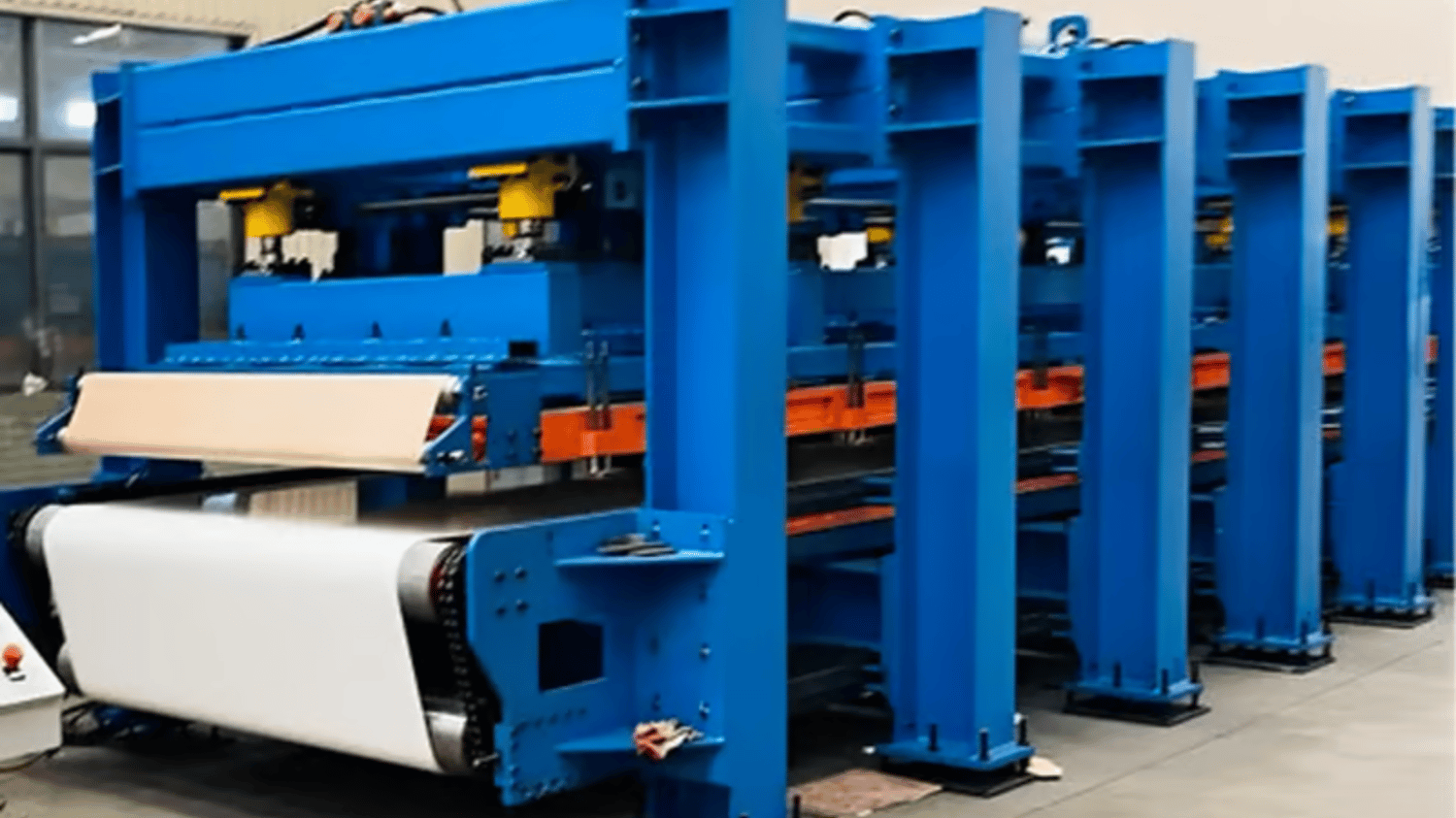

A 1 + 1 continuous laminating machine is an industrial equipment that is designed to laminate and bond various materials together, such as films, foils, papers, and fabrics. It is a continuous machine, meaning that it can laminate materials that are fed in a continuous manner, resulting in faster processing times and increased productivity. The 1 + 1 machine refers to the two laminating rollers that are used to apply adhesive or glue to the materials being laminated. Here are some of the benefits and uses of a 1 + 1 continuous laminating machine.

Improved Durability and Protection

The main benefit of using a 1 + 1 continuous laminating machine is that it provides an extra layer of durability and protection to the materials being laminated. This is particularly useful for materials that are exposed to harsh weather conditions, moisture, or wear and tear, such as packaging materials, banners, signage, and outdoor banners. The lamination process ensures that the printed surface stays intact and looks pristine, even after extended use.

Increased Aesthetics and Appeal

Aesthetics and appeal are crucial in designing and producing marketing and promotional materials. A 1 + 1 continuous laminating machine can add gloss, matte, or textured finishes to the laminated materials, depending on the desired outcome. This can enhance the appearance of logos, graphics, and images, and make them stand out, improving their visibility and memorability.

Efficient and Time-Saving

A 1 + 1 continuous laminating machine can process large volumes of materials and laminate them in a short amount of time. This makes it ideal for high-volume production runs and time-critical projects. The machine can handle different types of materials, from thin films to thick fabrics, and allows for adjustments in speed, temperature, and pressure, ensuring a consistent and quality laminating process.

Versatility and Adaptability

A 1 + 1 continuous laminating machine is versatile and can be used for a wide range of applications, from industrial to commercial use. It is adaptable to different types of materials, adhesives, and laminating techniques, making it suitable for diverse industries, such as packaging, printing, advertising, and manufacturing. It also allows for experimentation and customization, enabling businesses to produce unique and innovative laminated products.

Cost-Effective and Profitable

A 1 + 1 continuous laminating machine is a cost-effective and profitable investment for businesses that require reliable and efficient lamination services. The machine reduces the need for manual labor, which can be expensive and time-consuming, and increases production capacity, leading to higher profits and ROI. It also reduces material waste and errors, resulting in savings in materials and production costs.

Environmentally Friendly

A 1 + 1 continuous laminating machine promotes sustainability and eco-friendliness by reducing the use of harmful chemicals and waste. The machine uses safe and non-toxic adhesives, and the laminated materials can be recycled or reused, reducing the impact on the environment. Businesses that prioritize sustainability and green initiatives can benefit from using a 1 + 1 continuous laminating machine.

Quality Control and Assurance

A 1 + 1 continuous laminating machine provides a high level of quality control and assurance for laminated products. The machine can detect and rectify errors in lamination, such as bubbles, wrinkles, or misalignment, ensuring that the final product is defect-free and meets the required specifications. Using a 1 + 1 continuous laminating machine can boost customer satisfaction and loyalty by ensuring consistent and high-quality products.

Easy Maintenance and Operation

A 1 + 1 continuous laminating machine is easy to operate and maintain, even for non-experts or beginners. The machine comes with user-friendly controls and instructions, and requires minimal training and supervision. It also requires simple and routine maintenance procedures, such as cleaning and lubrication, to ensure that it operates smoothly and efficiently for a long time.

Industry Standards and Certifications

A 1 + 1 continuous laminating machine adheres to industry standards and certifications, ensuring that the laminated products meet the required quality and safety standards. The machine can produce laminated products that conform to FDA, ASTM, UL, or CE regulations, depending on the materials and applications. This can provide businesses with a competitive advantage and credibility in the industry.

Customizable and Innovative

A 1 + 1 continuous laminating machine enables businesses to customize and innovate their laminated products, according to their needs and preferences. The machine can handle various laminating techniques, such as thermal, hot, cold, or pressure-sensitive, and can apply different types of adhesives, such as acrylic, rubber, or solvent-based. This allows for creativity and experimentation in designing and producing laminated products that meet customers' demands and expectations.