Table of Contents

The rock wool composite board equipment provided by Shanghai Zhongji Machinery Co., Ltd. is a production line designed specifically for producing high-quality rock wool composite boards, integrating multiple advanced technologies to meet different building insulation, sound insulation, and fire protection needs. The following is an overview of the characteristics and capabilities of Shanghai Zhongji Rock Cotton Composite Board Equipment:

-

Production line configuration: the production line can realize a series of automated production processes from rock wool raw material processing, mixing, cotton cloth, composite to cutting, packaging, etc. Including dry powder mortar mixer, material metering system, elevator, insulation mortar storage device, packaging machine, and various conveying and storage devices.

-

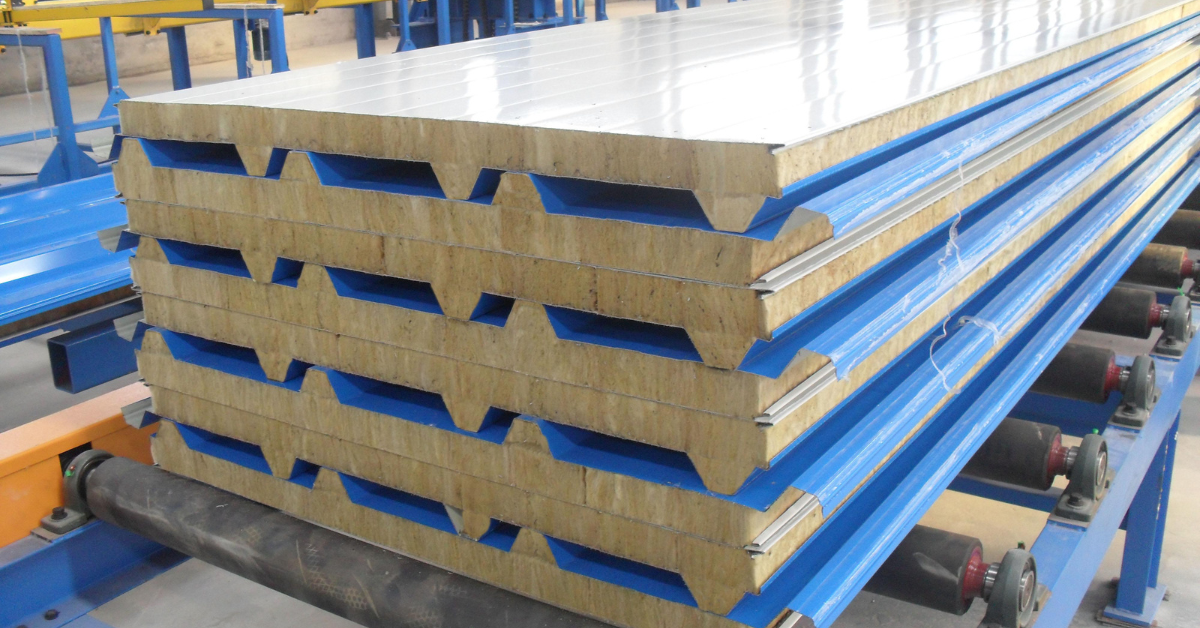

Rock wool processing capability: The equipment can handle high-density rock wool boards, such as achieving strip cutting, automatic conveying, 90 degree flipping, final forming, band saw cutting, automatic stacking, and winding packaging of 250mm thick rock wool boards, greatly improving production efficiency and product quality.

-

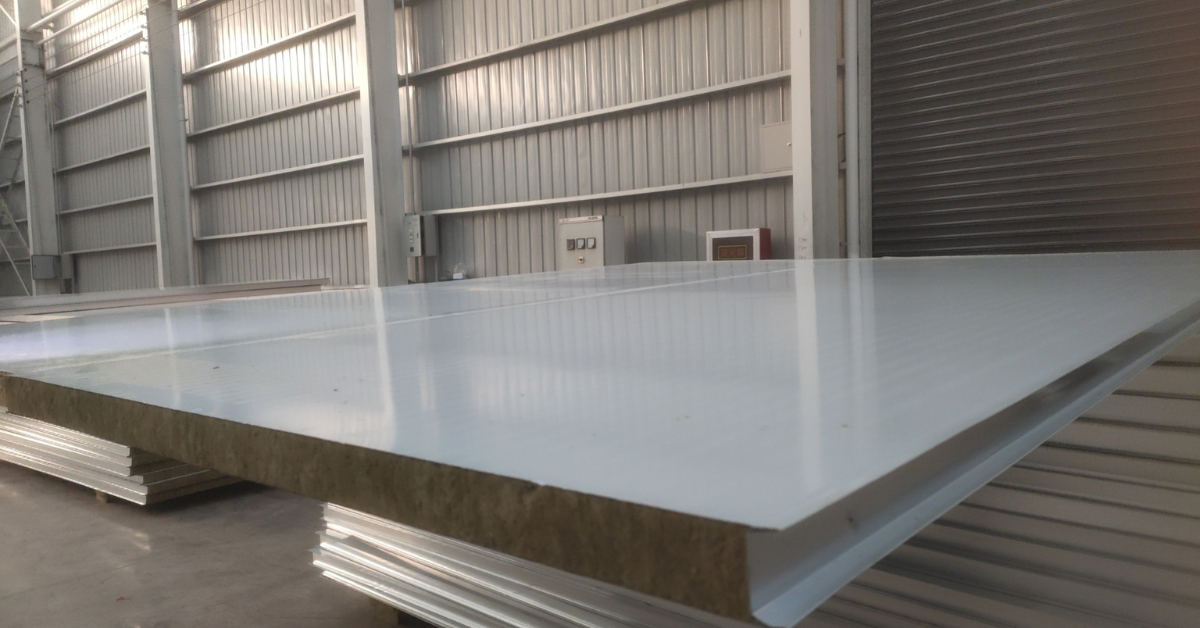

Multi functional composite ability: It can not only produce rock wool composite panels, but also produce polyurethane (PU) and rock wool composite color steel sandwich panels, as well as high standard rock wool color steel sandwich panels, suitable for different types of buildings and insulation requirements.

-

Technological Innovation: Shanghai Zhongji continuously innovates in equipment, such as the PU high-pressure foaming machine equipped with an accurate measurement system, ensuring the stability of the foaming process and product uniformity, meeting the production needs of high-performance products such as building fireproof panels and door panels.

-

Environmental Protection and Energy Conservation: Equipment design focuses on environmental protection and energy efficiency, such as reducing material waste in the production process, adopting energy-saving technologies to reduce energy consumption, and being compatible with the use of environmentally friendly adhesives and additives to produce products that meet green building standards.

-

Customized services: Shanghai Zhongji provides customized equipment solutions for different customer needs, allowing for adjustments to the configuration and functionality of production lines according to specific customer requirements to meet specific production specifications and output targets.

Shanghai Zhongji's rock wool composite board equipment, with its high efficiency, automation, flexibility, and environmental friendliness, serves the domestic and international markets, helping manufacturers increase production capacity, reduce costs, and expand product lines. It is one of the preferred equipment in the field of building insulation material production.

The development of rock wool composite board equipment has promoted the realization of environmental protection, efficiency, and customized production, providing more sustainable solutions for the global construction industry.