Table of Contents

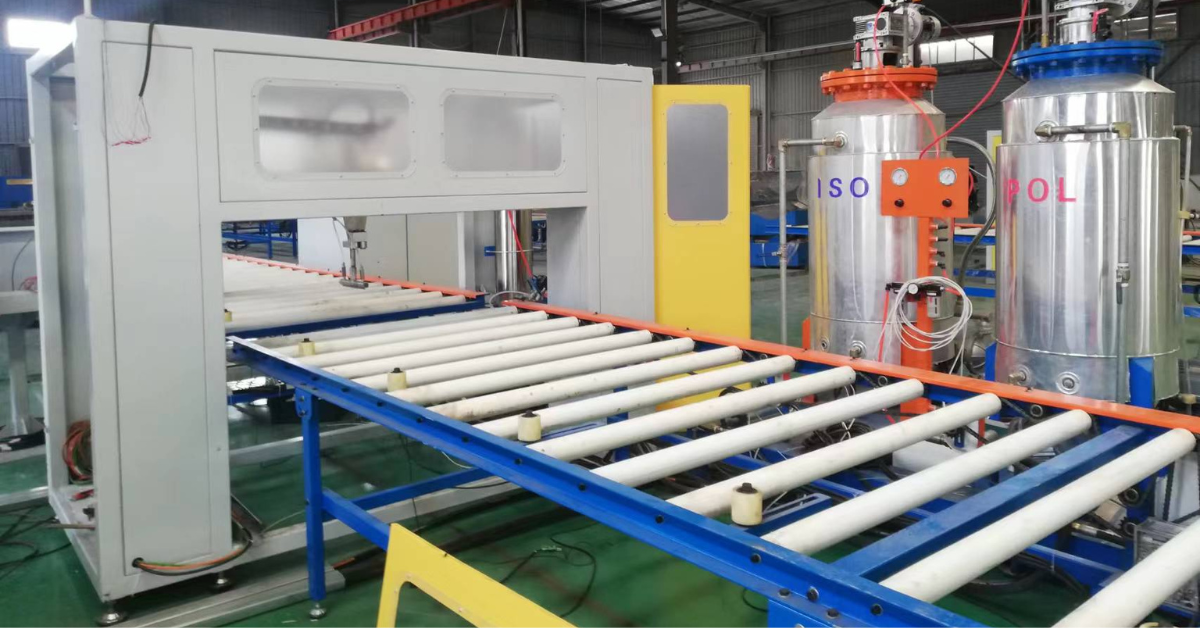

The purification board and aluminum honeycomb board glue spraying machine produced by Shanghai Zhongji Machinery Co., Ltd. currently has a speed of 14 square meters per minute, with a maximum of 22 square meters per minute. It has advantages such as high speed, stability, and reliability.

The Shanghai Zhongji gluing machine is designed for production lines that require precise and efficient gluing processes, especially suitable for gluing large-area materials such as composite boards and colored steel plates. Its main characteristics include:

-

Automation and Intelligence: Modern manufacturing pursues automated production processes. The glue spraying machine integrates advanced control systems and sensor technology to achieve precise glue quantity control, automatic adjustment, and fault warning, reducing manual intervention and improving production efficiency and consistency.

-

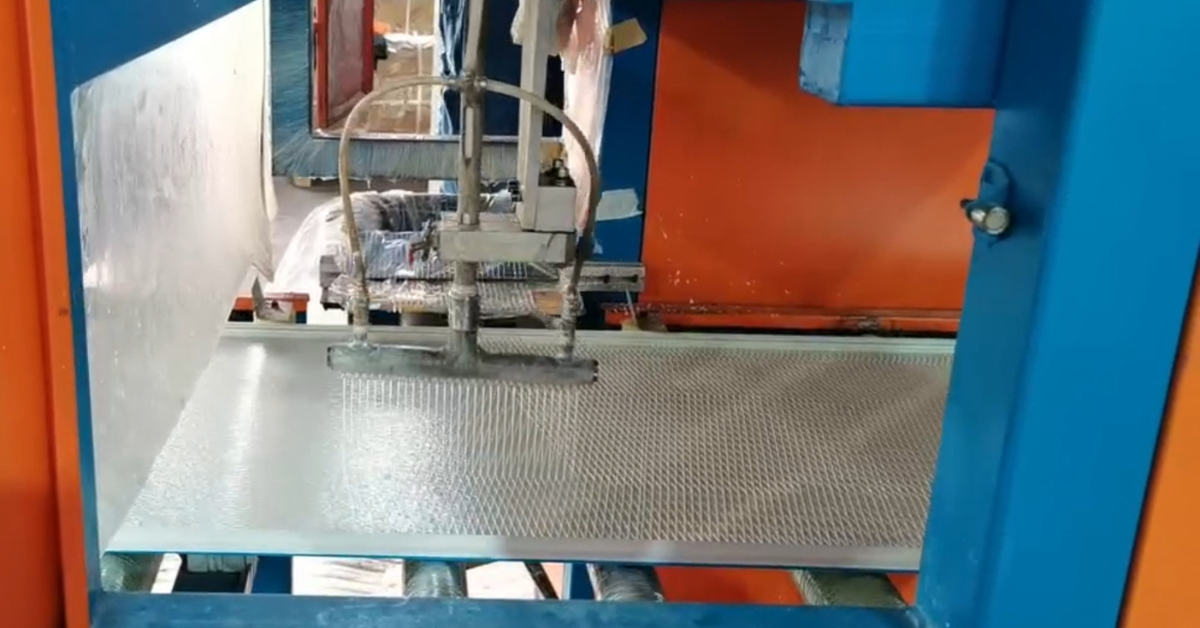

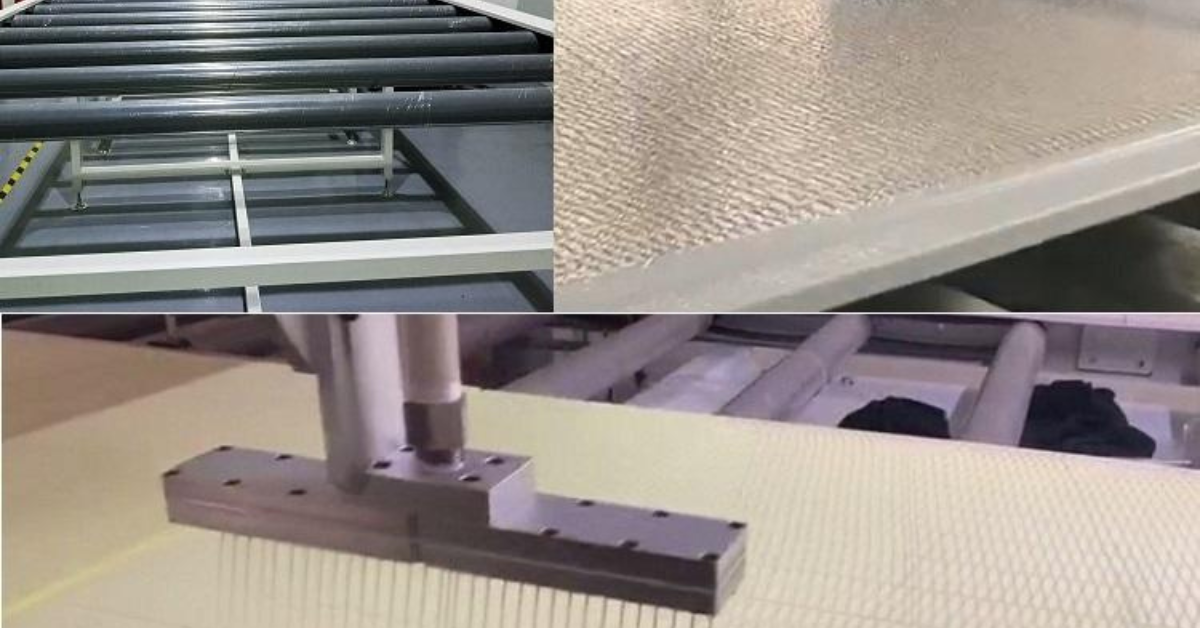

Accurate coating: High-quality products often require glue or other adhesives to be evenly coated without bubbles. The glue spraying machine ensures the accuracy and repeatability of coating thickness through a precise pumping system and uniformly distributed nozzle design, improving the yield and product quality.

-

Pumping system: equipped with both pump A and pump B, both designed as gear pumps, ensuring the continuous stability and accuracy of glue delivery, which is crucial for maintaining product quality.

-

Automatic cleaning function: The device has a convenient one-click automatic cleaning function, especially for the mixing part, making equipment maintenance and switching of rubber materials more efficient and fast.

-

Heating function: To ensure the optimal fluidity and bonding effect of the adhesive, The barrel, pipeline, and pump are all equipped with a heating function, and the temperature control range is generally between 30-50 ℃, which helps to maintain good adhesive performance even in low-temperature environments.

-

Conveyor line design: The glue pouring conveyor line adopts standard linear modules combined with high-quality imported servo motors to ensure smooth and precise positioning during the conveying process. The conveyor line type is a power drum conveyor line, suitable for passing boards of different sizes and weights.

- Wide application range: Shanghai Zhongji's glue spraying machine is suitable for multiple industries, including building materials, furniture, textiles, automobiles, sports goods, etc., especially for the production of composite boards with high requirements for glue coating area and uniformity, such as the production of special purpose boards such as RV carriage boards and refrigerated cars.

In modern manufacturing, the glue spraying machine, as one of the key production equipment, plays a crucial role in achieving high efficiency and high-quality production. The characteristics of the Shanghai Zhongji glue dispenser reflect its advantages in automation, efficiency, and flexibility, meeting the needs of the modern manufacturing industry for high efficiency and high-quality production.