Table of Contents

In modern industrial manufacturing, purification board production lines are changing the future trend of manufacturing with high automation and production efficiency.

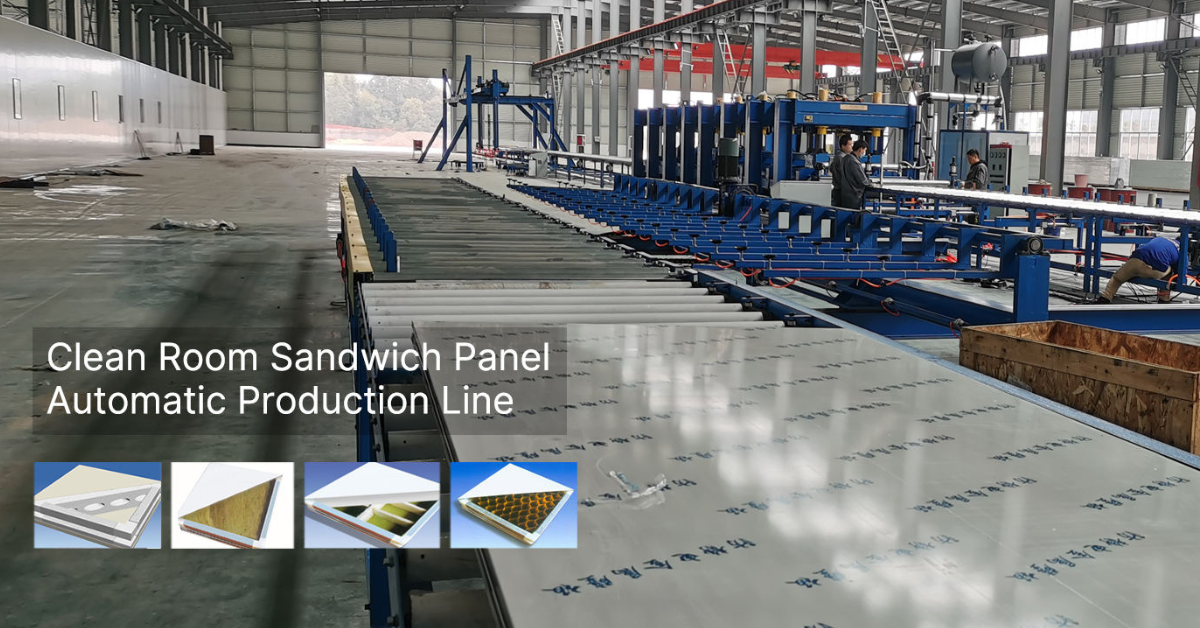

Our purification board production line is composed of various equipment such as a hydraulic uncoiling system, steel plate film cutting system, leveling system, cold bending forming machine system, and glue spraying system, constructing a complete and efficient production system.

The purification board production line shows innovation and progressiveness in technical application. It adopts mature roll-forming technology, HCFC polyurethane foaming technology, and composite transmission technology at home and abroad. In addition, the integration of numerical control servo control technology and frequency conversion vector control technology makes the operation of the whole production line more accurate and efficient.

The automation level of the purification board production line is high, which not only significantly improves production efficiency but also reduces operational difficulty. The entire line only requires five to seven operators to operate normally, which greatly reduces labor costs and also reduces the workload of operators.

From the perspective of production cost and return, our purification board production line also demonstrates significant advantages. Through efficient production processes and technological innovation, not only have production costs been significantly reduced, but also higher returns have been provided to enterprises.

The hydraulic control technology used in the purification board production line ensures the stability and safety of the production process. Each link is carefully designed and strictly controlled to ensure the quality and performance of the final product.