Introduction

Packing boxes play a crucial role in ensuring products are delivered safely and securely. Double layer packing boxes provide added durability and strength, making them a popular choice for many businesses. A

Double layer packing box roll forming machine is a valuable investment, enabling businesses to produce high-quality packaging solutions in-house, reducing costs and increasing efficiency.

What is a Double Layer Packing Box Roll Forming Machine?

A double layer packing box roll forming machine is a piece of equipment specifically designed to manufacture double layer packing boxes. The machine uses a continuous process to roll multiple flat sheets of cardboard or corrugated material into the desired shape. A double layer packing box roll forming machine is capable of producing boxes of various sizes and thicknesses, ensuring businesses can meet their specific packaging needs.

The Benefits of a Double Layer Packing Box Roll Forming Machine

Investing in a double layer packing box roll forming machine offers numerous benefits for businesses. Firstly, it eliminates the need for outsourcing box production. This means businesses can produce their own boxes on-site, saving both time and money. Secondly, a double layer packing box roll forming machine offers increased efficiency and productivity. With automated processes, a machine can produce a high volume of boxes in a short period, ultimately enabling businesses to meet demand easily.

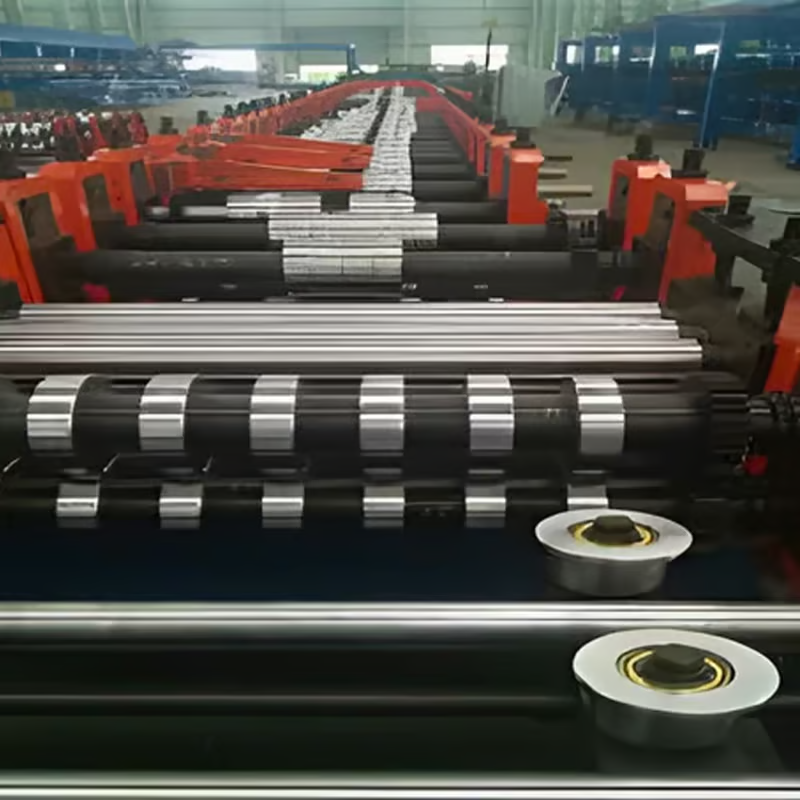

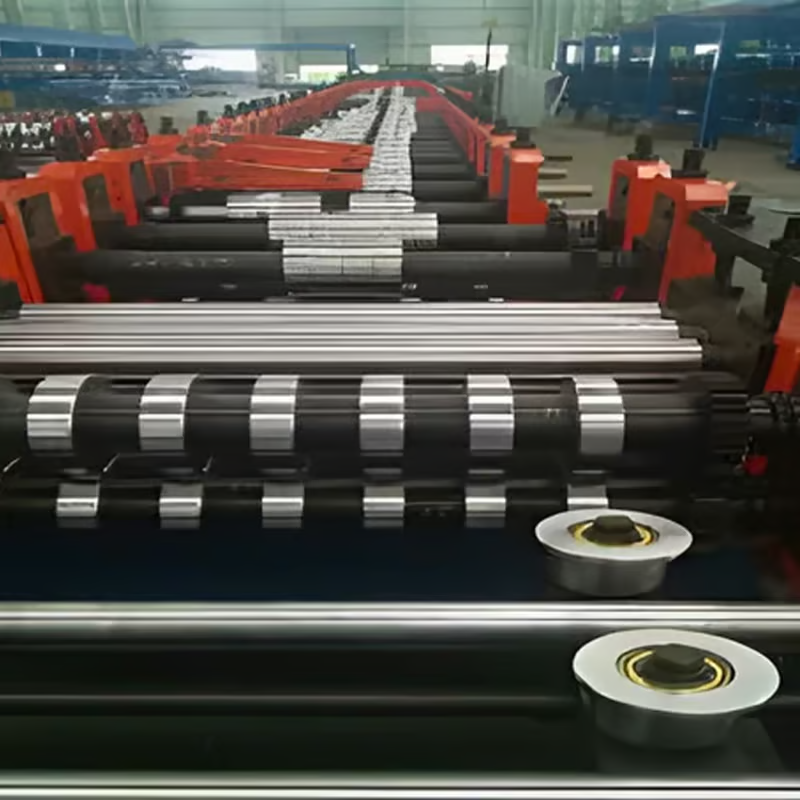

The Design of a Double Layer Packing Box Roll Forming Machine

A double layer packing box roll forming machine is designed with a series of rollers and cutters that are capable of forming the desired box shape. The machine is designed to work with a range of materials such as cardboard, corrugated board, and paperboard. The versatility of a double layer packing box roll forming machine enables businesses to tailor their packaging solutions to fit their specific needs.

How Does a Double Layer Packing Box Roll Forming Machine Work?

The working principle of a double layer packing box roll forming machine is simple. The machine feeds flat sheets of materials into the rollers, which then form the sheets into the desired shape. The machine then uses cutters to cut the box to the required size. The boxes are then stacked and ready for packaging.

The Importance of Quality in Double Layer Packing Box Roll Forming Machines

Investing in a high-quality double layer packing box roll forming machine is essential for businesses. A machine that is built from quality materials and components will deliver top-notch performance, enabling businesses to make superior boxes. Additionally, a high-quality machine will last longer, reducing the need for frequent repairs and maintenance.

Considerations When Choosing a Double Layer Packing Box Roll Forming Machine

When selecting a double layer packing box roll forming machine, there are several factors to consider. Firstly, businesses should consider the size of the machine. Larger machines can produce a higher volume of boxes, but they also require more space. Secondly, businesses should consider the types of materials they will use to produce boxes. The machine should be capable of working with different materials. Lastly, the price of the machine should be considered. While a cheaper machine may seem appealing, investing in a high-quality machine will ultimately deliver better performance and a longer lifespan.

Uses for Double Layer Packing Boxes

Double layer packing boxes are ideal for transporting fragile and heavy products as they offer increased strength and durability. These boxes are commonly used in industries such as manufacturing, automotive, and shipping. They are also used in food packaging to provide additional protection.

The Future of Double Layer Packing Box Roll Forming Machines

Advancements in technology and manufacturing processes are leading to the development of more sophisticated double layer packing box roll forming machines. These machines offer increased efficiency, speed, and accuracy, enabling businesses to produce boxes of superior quality.

Conclusion

A double layer packing box roll forming machine is an essential investment for businesses in need of high-quality packaging solutions. The machine offers numerous benefits, including increased efficiency and productivity, reduced costs, and the ability to tailor packaging to fit specific needs. By selecting a quality machine, businesses can reap the rewards of a reliable and efficient manufacturing process.

Quote Inquiry

Contact us!