Introduction

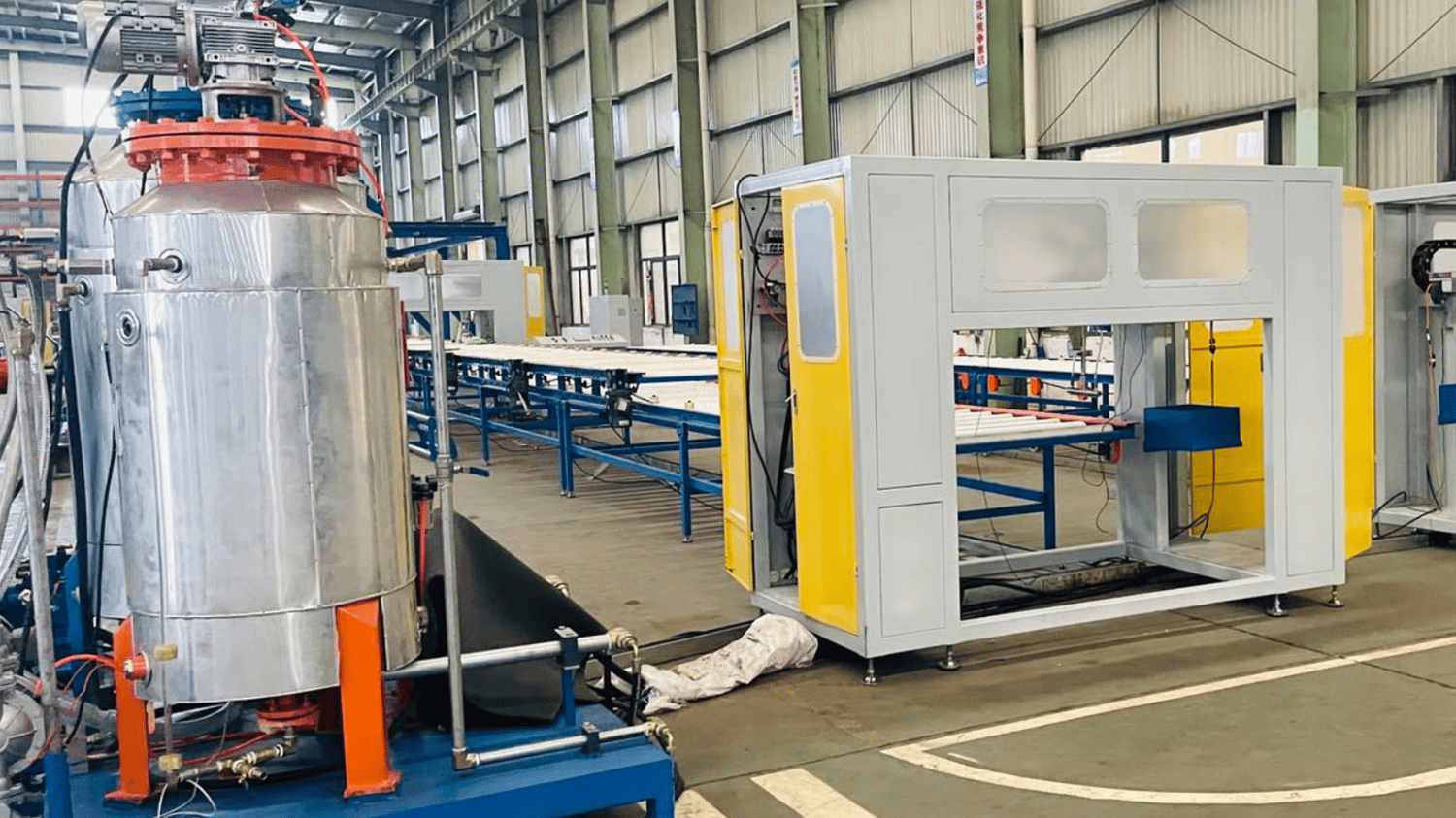

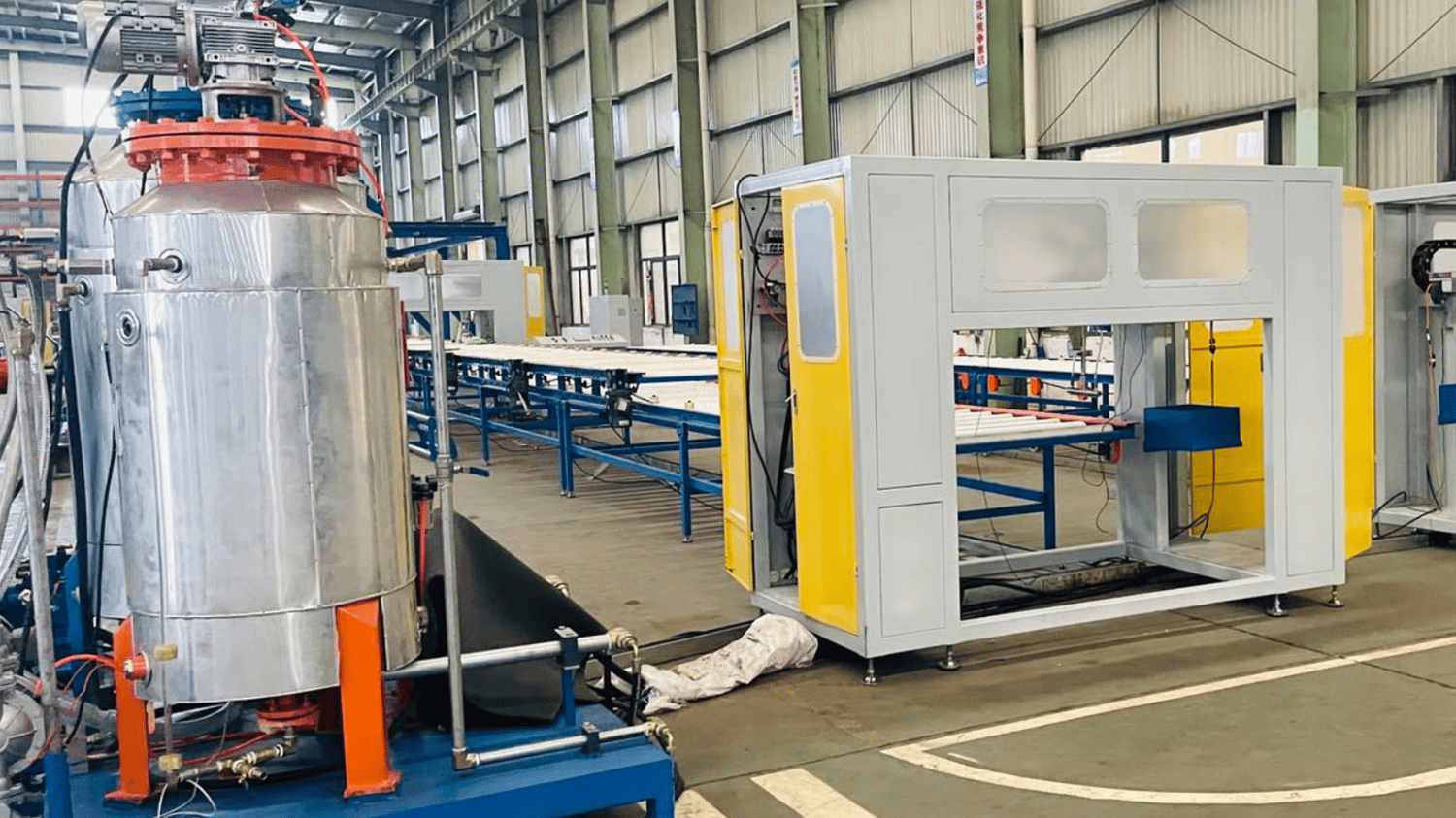

If you are in the construction business, you must know how important it is to have sturdy and reliable structures. Sandwich panels are made up of two exterior layers of material, such as metal, and an interior layer of insulation, such as foam. They are used to create highly efficient and durable walls, roofs, and floors in various commercial and industrial buildings. One crucial component of sandwich panel manufacturing is the glue spraying system. This article will delve deeper into how a

Sandwich panel glue spraying system can benefit your business.

Easy to Use

The sandwich panel glue spraying system is straightforward to operate. It is designed to distribute the glue evenly onto the panels, which ensures a stronger adhesion. The system comes with an instruction manual and requires minimal training for the operator. The ease of use minimizes the likelihood of errors and decreases production time.

Efficient Glue Application

Another advantage of using a sandwich panel glue spraying system is efficient glue application. The system is designed to optimize glue usage, ensuring that there is even and consistent coverage on the panels. This results in less waste, which can translate into cost savings for your business. Efficient glue application also ensures that the sandwich panels are lightweight and easy to assemble.

Improved Quality Control

The glue spraying system allows for better quality control in sandwich panel manufacturing. The system evenly distributes the glue, which results in a uniformly strong bond. This ensures that the sandwich panels meet the required standards for strength, insulation, and durability. Improved quality control also leads to higher levels of customer satisfaction.

Customizable Settings

The sandwich panel glue spraying system comes with customizable settings that allow you to adjust the glue application based on your specific needs. You can adjust the amount of glue applied, the pattern of the spray, and the speed of the application. This flexibility allows you to create sandwich panels that meet specific design and construction requirements.

Increased Productivity

The sandwich panel glue spraying system increases productivity in your manufacturing process. The system allows for faster glue application, which means faster panel production. The efficient glue application also means that there is less time spent waiting for the glue to dry. Faster production times mean that you can take on more projects and increase your revenue.

Low Maintenance

The sandwich panel glue spraying system is low maintenance. It is designed to minimize downtime and maximize uptime. The system is made up of high-quality components that require little maintenance. This means that you can spend more time producing sandwich panels and less time maintaining the glue spraying system.

Cost-effective

Investing in a sandwich panel glue spraying system can be cost-effective in the long run. The system improves the efficiency and quality of your manufacturing process, which can lead to cost savings. You can also produce more sandwich panels in a shorter amount of time, which means that you can take on more projects and increase your revenue.

Environmentally Friendly

The sandwich panel glue spraying system is environmentally friendly. The system minimizes glue waste, which reduces environmental impact. Effortlessly reducing waste makes your business ecologically responsible while also reducing costs.

Consistent Results

Finally, the sandwich panel glue spraying system provides consistent results. The precise application of glue ensures that there are no weak spots in the sandwich panel's glue layer. Consistent results mean that you can produce high-quality sandwich panels every time, which leads to satisfied customers and increased business.

Conclusion

The sandwich panel glue spraying system is a crucial component of the manufacturing process for sandwich panels. It provides significant advantages such as easy operation, efficient glue application, improved quality control, customizable settings, increased productivity, low maintenance, cost-effective, environmentally friendly, and consistent results. Investing in a sandwich panel glue spraying system can improve your business's efficiency and quality, ultimately leading to increased revenue and customer satisfaction.

Quote Inquiry

If you have any questions, please let us know asap!