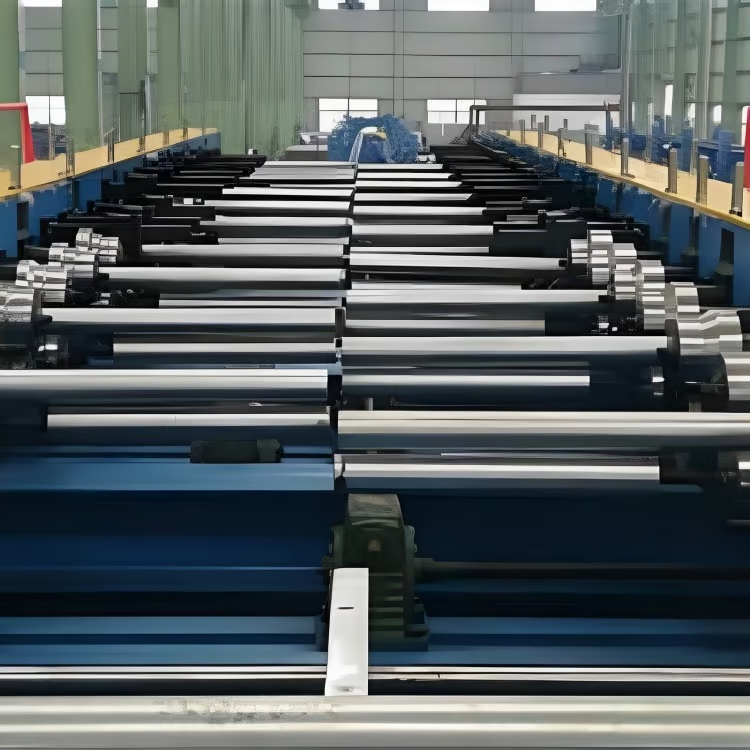

Efficiency and Precision

An

Upper roll forming machine is designed to efficiently and precisely create complex shapes out of metal sheets. The machine uses a series of rollers to gradually shape the metal into the desired form, ensuring accurate results every time.

Versatility

One of the key benefits of an upper roll forming machine is its versatility. This machine can be used to create a wide range of products, from simple tubes and pipes to more complex profiles and sections. This makes it an essential tool for manufacturers in various industries.

Cost-Effective Production

Using an upper roll forming machine can help manufacturers reduce production costs significantly. The machine operates quickly and efficiently, leading to increased productivity and lower labor costs. Additionally, the ability to create multiple shapes with a single machine saves money on equipment and tooling expenses.

High Quality Output

Upper roll forming machines are known for producing high-quality output consistently. The machine's precise shaping capabilities result in products with tight tolerances and smooth surfaces. This is essential for industries that require precision-engineered components.

Customization Options

Manufacturers can easily customize their products with an upper roll forming machine. By adjusting the machine settings, operators can create unique shapes and profiles to meet specific customer requirements. This flexibility allows for greater creativity and innovation in product design.

Reduced Material Waste

The efficient nature of an upper roll forming machine helps minimize material waste during the production process. By accurately shaping metal sheets, the machine ensures that only the necessary amount of material is used, reducing scrap and lowering overall material costs.

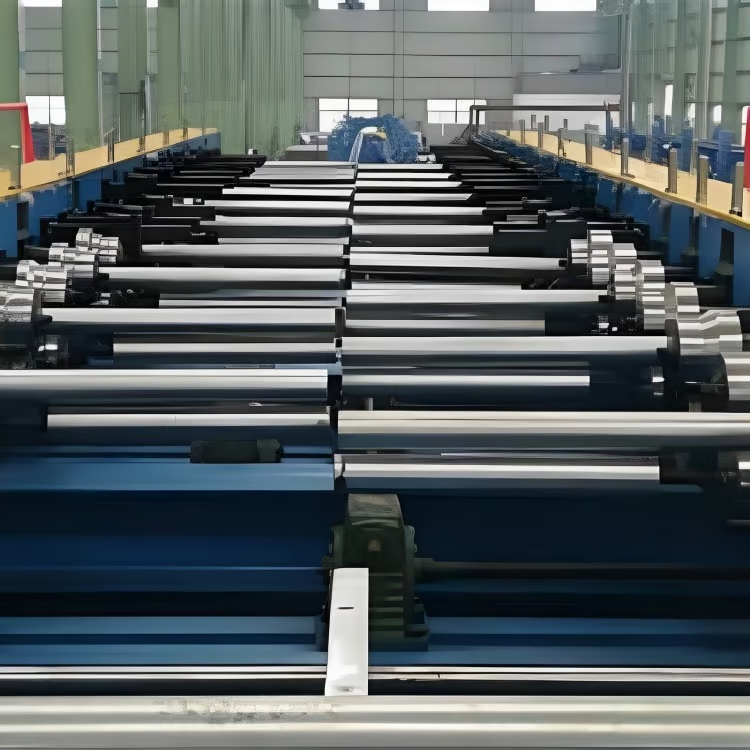

Increased Production Speed

Compared to traditional manufacturing methods, an upper roll forming machine offers significantly faster production speeds. The continuous rolling process allows for rapid shaping of metal sheets, leading to quicker turnaround times and increased output.

Minimal Maintenance Required

Upper roll forming machines are designed to be durable and low-maintenance. With regular servicing and upkeep, these machines can operate smoothly for years without significant issues. This reliability ensures consistent production without unexpected downtime.

Improved Safety Features

Modern upper roll forming machines are equipped with advanced safety features to protect operators and prevent accidents. Automated controls, safety guards, and emergency stop buttons help create a secure working environment for machine operators.

Enhanced Automation Capabilities

Many upper roll forming machines come with automation capabilities that further streamline the production process. These machines can be integrated with robotic systems or computer-controlled technologies to automate material handling, shaping, and finishing tasks.

Quote Inquiry

Contact us!