Table of Contents

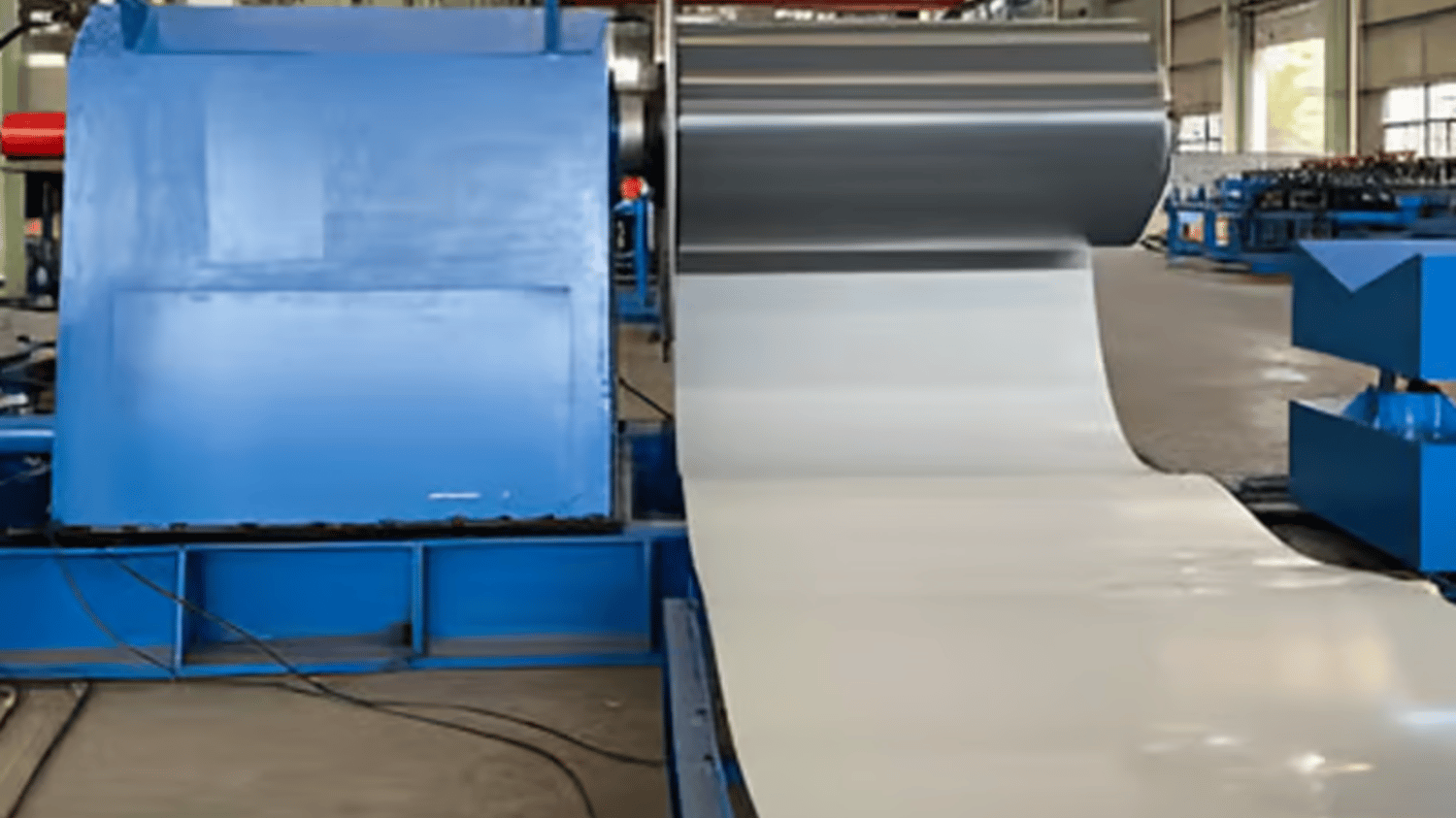

The Introduction of Hydraulic uncoilers

A hydraulic uncoiler is a type of machine that is used in a variety of industries to uncoil materials like metal strips, wire coils, and other flat stock materials. It is an essential piece of equipment in the steel, automotive, and machinery industries. Hydraulic uncoilers are designed to unwind coils of material with minimal resistance, speed, and efficiency, thereby reducing the required manual labor. In this article, we will discuss the benefits of using hydraulic uncoilers.

The Benefits of Hydraulic Uncoilers

Increased Efficiency

Hydraulic uncoilers are designed to increase efficiency by reducing the time it takes to unwind a coil of material. With traditional uncoiling methods, the material is often unwound manually, leading to slower processing times. With hydraulic uncoilers, the operator has more control over the speed and tension of the uncoiling process, enabling faster production. This allows for more efficient operation, leading to increased productivity and profitability.

Reduced Labor Costs

Hydraulic uncoilers are designed to reduce the amount of manual labor required to uncoil materials. With traditional uncoiling methods, multiple people are needed to handle a coil of material, leading to increased labor costs. With hydraulic uncoilers, only one operator is needed, reducing overall labor costs. This also reduces the risk of injury to employees, minimizing workers' compensation claims and downtime.

Improved Safety

Hydraulic uncoilers are engineered with safety in mind. They have safety features like automatic braking mechanisms, safety guards, and other safety functions. These features protect operators and workers from injury due to machine malfunction or human error. The automatic braking mechanism stops the machine immediately if the material is jammed or if there is a power failure. This reduces the risk of injury, property damage as well as saves on the repair and maintenance costs.

Reduced Material Waste

Traditional uncoiling methods can result in material waste. The process of manually uncoiling material can lead to defects or damage, resulting in spoilage of material. With hydraulic uncoilers, the material is uncoiled with minimal stress and tension, which reduces the likelihood of damage or defects. This leads to a reduction in material waste, increasing overall profitability for the business.

Easy to Operate

Hydraulic uncoilers are designed to be user-friendly, with easily accessible buttons, controls, and displays. Operators can easily adjust the machine settings to accommodate different materials, coil sizes, and other requirements. With intuitive controls and displays, operators can easily monitor machine performance, making it easy to identify and correct any issues that may arise.

Increase Material Accuracy

Hydraulic uncoilers are designed to provide precise and consistent material unwinding. The machine applies consistent tension to the coil of material, leading to a more consistent unwinding process. This results in greater accuracy in the final product. Consistent unwinding promotes a more efficient manufacturing process, which can lead to better quality control and increased customer satisfaction.

Increased Capacity

Hydraulic uncoilers are designed to handle larger coils of material than traditional uncoiling methods. Larger coils can be more difficult to handle and require more manual labor, which can slow down production and increase labor costs. Hydraulic uncoilers allow for the handling of larger coils, which increases capacity and productivity.

Reduced Maintenance Costs

Hydraulic uncoilers are engineered to be low-maintenance machines. They require minimal attention and upkeep, reducing the overall maintenance costs over time. Routine maintenance, such as checking the hydraulic oil and cleaning the machine, can be done quickly and easily, with little machine downtime. This reduces repair and maintenance fees as well as increases profit margins.

Longevity and Durability

Hydraulic uncoilers are designed to be durable and long-lasting. The machine is constructed with high-quality materials that can withstand heavy use and harsh conditions. It has a sturdy frame designed to withstand the high tension of material unwinding. The durability of the hydraulic uncoiler means that the machine will last longer with less frequent repairs, ultimately saving you money.

Versatility

Hydraulic uncoilers are designed to accommodate a wide range of materials, from thin wires to heavy metals. This versatility allows for greater flexibility in production. The machine can handle a variety of materials, reducing the need for additional machinery, leading to lower equipment costs and increased profitability.

Summary

Hydraulic uncoilers are essential pieces of machinery in many industries. They reduce labor costs, improve safety and increase efficiency. Overall, hydraulic uncoilers improve the bottom line, lead to increased profitability, and improve customer satisfaction.