Table of Contents

EPS Automatic Block Cutting Machine: The Future of Construction

Do you want to improve your construction process? Do you need a reliable machine to cut EPS blocks for your project? An EPS automatic block cutting machine can revolutionize your workflow and improve the quality of your final products. Here's everything you need to know about this cutting-edge technology.

What is an EPS Automatic Block Cutting Machine?

EPS stands for Expanded Polystyrene, a lightweight material widely used in construction for insulation, decoration, and modeling. An automatic block cutting machine is a device that can precisely slice and shape EPS blocks according to specific requirements. Together, an EPS automatic block cutting machine can automate and streamline the process of cutting EPS blocks, saving time, labor costs, and minimizing errors.

How does an EPS Automatic Block Cutting Machine work?

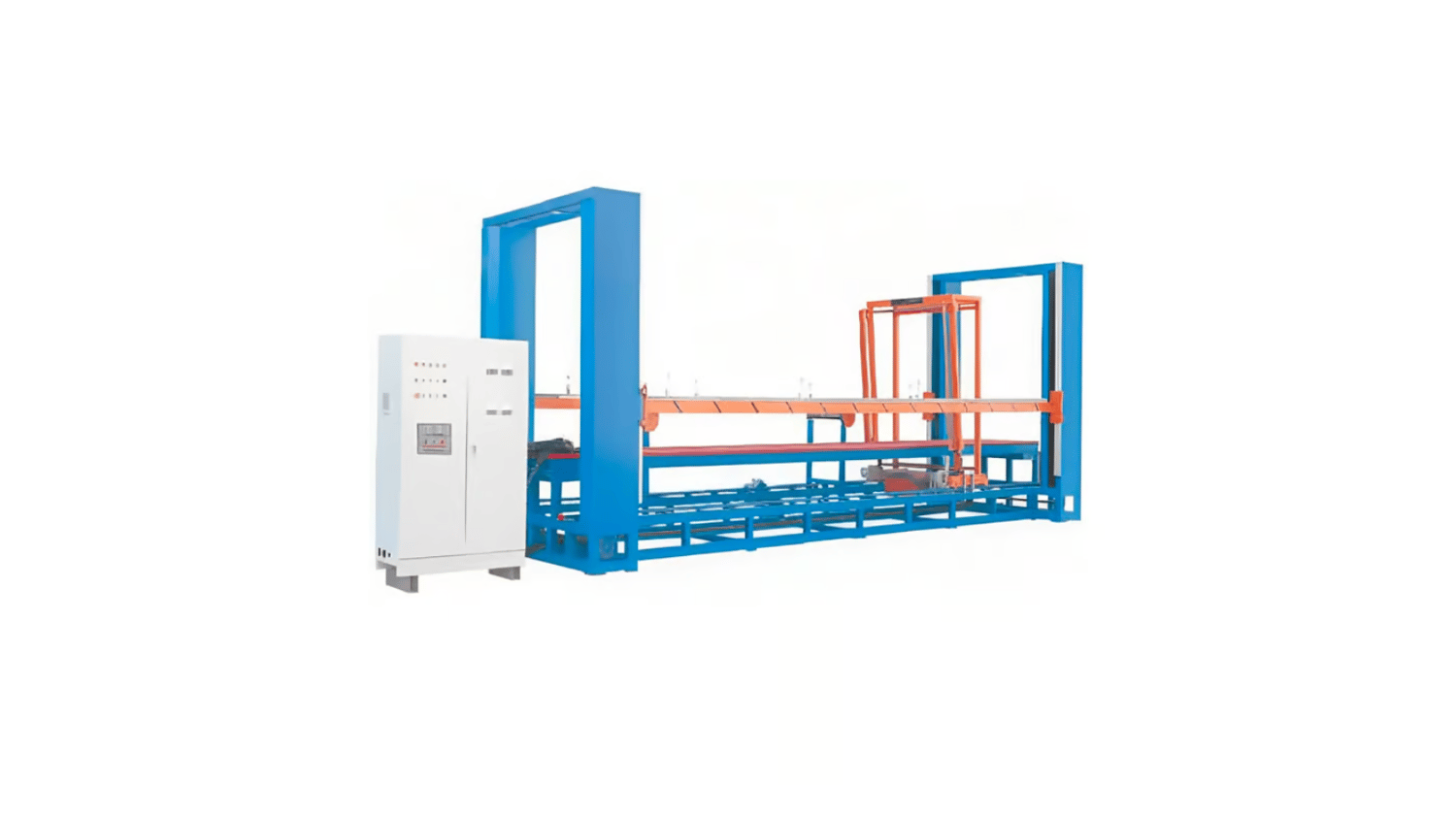

The working principle of an EPS automatic block cutting machine involves several components, including a hot wire, an electro-mechanical system, a computer-aided control unit, and a conveyor belt. Once you load the EPS block onto the conveyor belt, the hot wire will heat and melt the material to create a clean and accurate cut. The cutting parameters can be programmed and adjusted through the control unit, ensuring consistent and precise results.

What are the advantages of using an EPS Automatic Block Cutting Machine?

Compared to traditional methods of cutting EPS blocks, an automatic block cutting machine offers several advantages:

- Fast and efficient: you can cut multiple blocks in a matter of minutes, thanks to the automated process.

- Accurate and consistent: the machine can cut EPS blocks with high precision, reducing the chances of human errors and waste.

- Versatile and flexible: you can program the machine to cut EPS blocks into various shapes and sizes, depending on your project's requirements.

- Clean and safe: using an automatic cutting machine reduces the risk of accidents, injuries, and dust particles caused by manual cutting.

What are the types of EPS Automatic Block Cutting Machine?

EPS automatic block cutting machines come in different models and specifications, depending on the application and budget. Some common types are:

- Batch type machine: it can cut EPS blocks in bulk, typically in a range of 1200 mm x 600 mm x 350 mm.

- Linear type machine: it can cut EPS blocks continuously, up to a length of 4000 mm and a width of 1250 mm.

- CNC cutting machine: it uses a computer numerical control system to cut EPS blocks in complex shapes and patterns, offering high-speed and accuracy.

What are the key features to look for in an EPS Automatic Block Cutting Machine?

Before you buy an EPS automatic block cutting machine, consider the following features:

- Cutting speed: how many blocks per hour can the machine cut?

- Cutting size: what is the maximum and minimum size of EPS blocks the machine can cut?

- Cutting accuracy: what is the tolerance level of the machine's cut?

- Cutting angle: can the machine cut EPS blocks at different angles?

- User interface: how easy is it to operate the machine?

- Cutting wire: what type of wire does the machine use and how often does it need to be replaced?

- Safety measures: what safety features does the machine have, such as emergency stop button, thermal protection, and dust collection system?

What are the maintenance and operating costs of an EPS Automatic Block Cutting Machine?

Like any machinery, an EPS automatic block cutting machine requires regular maintenance and replacement of parts to ensure optimal performance and longevity. The operating costs of the machine may depend on various factors, such as the frequency of use, the quality of materials, and the electricity consumption. To minimize the costs, you can consider factors such as:

- Choosing a machine with a low power rating and energy-efficient components

- Buying high-quality wires and blades to reduce wear and tear

- Scheduling routine maintenance and cleaning to avoid breakdowns and repairs

Where can you buy an EPS Automatic Block Cutting Machine?

An EPS automatic block cutting machine is a capital investment that requires careful consideration and research. You can find these machines in construction equipment suppliers, machinery manufacturers, and online marketplaces. Before buying, make sure to compare prices, features, warranties, and customer reviews to make an informed decision.

What are the applications of an EPS Automatic Block Cutting Machine?

EPS automatic block cutting machines have various applications in the construction industry, such as:

- Insulation panels for roofs, walls, floors, and pipes

- Decorative elements for facades, columns, cornices, and moldings

- Architectural models and art installations

- Blocks for packaging and transport

What are the future developments in EPS Automatic Block Cutting Machine?

The EPS automatic block cutting machine is a relatively new technology, but it has already shown great potential in improving the efficiency and quality of construction processes. The future developments in this field may include:

- Integration with robotics and AI technology to enhance automation and precision.

- Development of new cutting materials and techniques to expand the range of applications.

- Improvement of safety and environmental standards to make the machines more sustainable and eco-friendly.