Table of Contents

The Ultimate Guide to Uncoilers: Everything You Need to Know

Uncoilers play a crucial role in the metal coil processing industry. They are utilized for unwinding coiled materials so that they can be further processed or formed into final shapes. From the automotive to the aerospace industry, uncoilers are necessary for many manufacturing processes. In this article, we will explore the various aspects of uncoilers and their importance in various industrial applications.

What Is an Uncoiler?

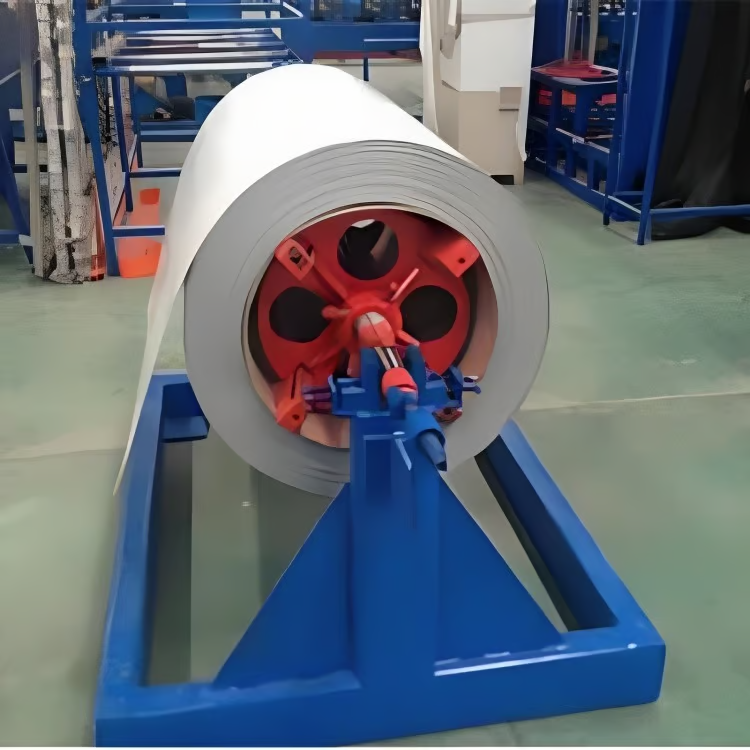

Uncoilers are machines that are used to unwind rolled or coiled materials, typically metal coils, for further processing, fabrication, or welding. It comprises of a spindle around which the coiled material is wound and a drive mechanism that helps to unwind the coil at a controlled rate. These machines are often used in manufacturing plants that produce metal sheets, tubing, and other materials that require a flat shape.

Types of Uncoilers

Uncoilers come in a variety of shapes and sizes, depending on the needs of the manufacturer. Some of the most common types of uncoilers are:

- Mandrel Uncoilers: These uncoilers use a mandrel to hold the coil in place while unwinding it.

- Single Arm Uncoilers: These uncoilers use a single arm to hold the coil while unwinding it.

- Double Arm Uncoilers: These uncoilers use two arms to hold the coil while unwinding it.

- Motorized Uncoilers: These uncoilers use a motorized mechanism to unwind the coil.

Importance of Uncoilers

Uncoilers are an essential part of the metal fabrication process. They are used to unwind metal coils so that they can be further processed into flat sheets, tubing, or other shapes. Without uncoilers, manufacturers would have a hard time producing these products and meeting customer demands.

How Do Uncoilers Work?

Uncoilers work by feeding the coiled metal through a series of rollers that flatten the material and prepare it for further processing. The coiled metal is fed into the uncoiler and is gripped by the mandrel or arms. The spindle then begins to rotate, unwinding the coil at a controlled rate. As the metal is fed through the rollers, it becomes flattened and ready for further processing.

Advantages of Using Uncoilers

There are several advantages to using uncoilers in manufacturing plants, including:

- Increased productivity: Uncoilers can unwind metal coils at a faster rate than manual methods, increasing overall productivity in the manufacturing plant.

- Improved safety: Uncoilers have safety features that prevent accidents and injuries, reducing the risk of workplace accidents.

- Reduced material waste: Uncoilers can unwind metal coils with minimal waste, ensuring that manufacturers are using their materials efficiently.

- Consistent quality: Uncoilers can produce consistent quality products, ensuring that each product meets the same specifications and standards.

Applications of Uncoilers

Uncoilers are used in a variety of applications, including:

- Automotive: Uncoilers are used to produce metal sheets for cars, trucks, and other vehicles.

- Aerospace: Uncoilers are used to produce metal sheets and tubing for airplanes, satellites, and other spacecraft.

- Construction: Uncoilers are used to produce metal sheets and tubing for buildings and other structures.

- Manufacturing: Uncoilers are used in various manufacturing processes to produce metal sheets, tubing, and other materials.

Choosing the Right Uncoiler

Choosing the right uncoiler depends on several factors, such as the size and weight of the metal coil, the required capacity, the desired production rate, and the level of automation required. Manufacturers should consider their specific needs and seek expert advice to ensure they choose the right uncoiler for their needs.

Maintenance of Uncoilers

Uncoilers require regular maintenance to ensure they function properly and provide consistent quality products. Manufacturers should follow the manufacturer's guidelines for maintenance, such as lubricating moving parts, cleaning the machine, and checking for wear and tear. Regular maintenance can help prolong the life of the machine and reduce the risk of breakdowns and downtime.

Conclusion

Uncoilers play a vital role in the metal manufacturing process. They are an efficient and reliable way to unwind metal coils for further processing and fabrication. By choosing the right uncoiler, maintaining it properly, and using it safely, manufacturers can improve their productivity, reduce material waste, and produce high-quality products that meet customer demands.