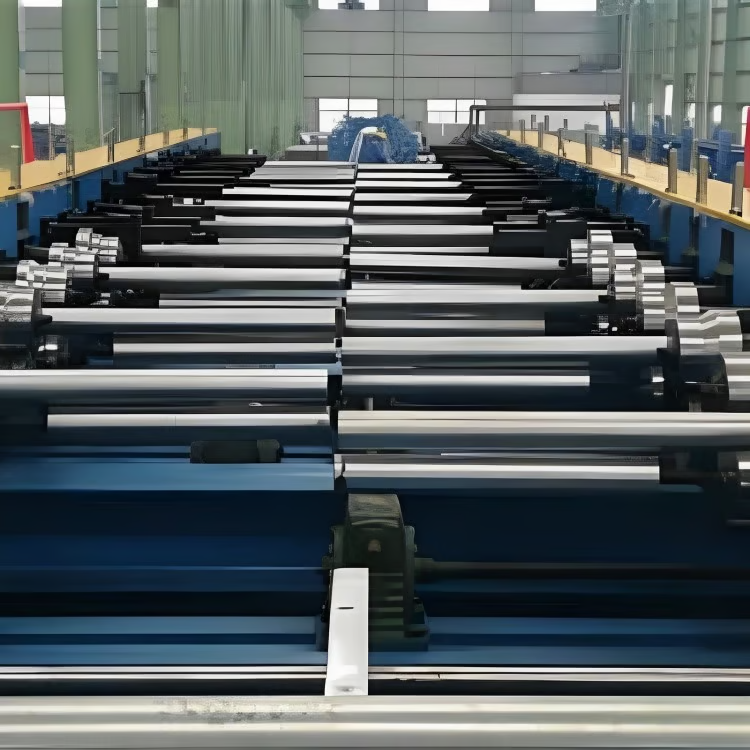

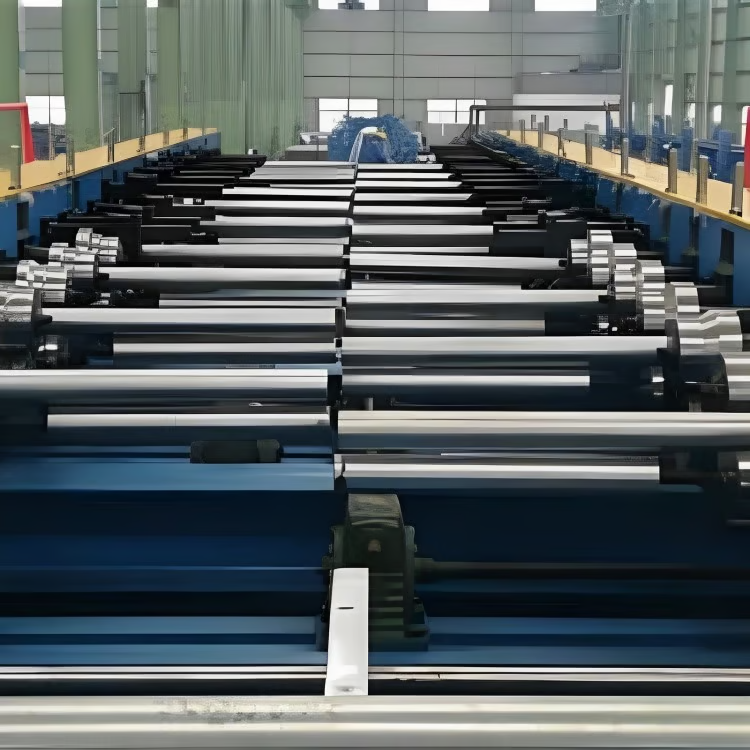

An upper roll forming machine is a type of machinery used in the metalworking industry to shape metal into desired profiles. It typically consists of a series of rollers that gradually bend the metal as it passes through, resulting in a finished product with a consistent cross-section.

How Does an Upper Roll Forming Machine Work?

The upper roll forming machine works by feeding a strip of metal through a series of rolls, each set of rolls gradually bending the metal into the desired shape. The machine is capable of forming complex cross-sections and can be used to produce a wide range of products such as panels, channels, and tubes.

Advantages of Using an Upper Roll Forming Machine

One of the main advantages of using an upper roll forming machine is its ability to produce high-quality, precise metal profiles with minimal waste. This can result in cost savings for manufacturers and a more efficient production process.

Applications of an Upper Roll Forming Machine

Upper roll forming machines are commonly used in the automotive, construction, and appliance industries to produce a variety of products such as roof panels, window frames, and shelving systems. They are also used in the manufacturing of components for HVAC systems and electrical enclosures.

Key Features to Consider When Choosing an Upper Roll Forming Machine

When selecting an upper roll forming machine, it is important to consider factors such as the machine's roll forming speed, the number of roll stations, the material thickness it can handle, and the types of profiles it can produce. These features will determine the machine's capabilities and suitability for specific applications.

Maintenance and Care Tips for Your Upper Roll Forming Machine

To ensure optimal performance and longevity of your upper roll forming machine, regular maintenance is crucial. This includes lubricating moving parts, checking for wear and tear, and keeping the machine clean to prevent debris buildup. Following manufacturer guidelines for maintenance will help extend the lifespan of your machine.

Common Troubleshooting Issues with Upper Roll Forming Machines

Some common issues that may arise with upper roll forming machines include misaligned rollers, material slipping, and irregular profiles. These problems can often be resolved by adjusting the machine settings, inspecting the rollers for damage, and ensuring proper material alignment.

Quality Control Measures for Upper Roll Forming Machine Products

Maintaining quality control is essential when using an upper roll forming machine to ensure that the finished products meet industry standards and customer requirements. This may involve conducting regular inspections, performing dimensional checks, and testing for strength and durability.

Future Trends in Upper Roll Forming Machine Technology

As technology continues to advance, we can expect to see improvements in upper roll forming machine technology, such as increased automation, enhanced precision, and faster production speeds. These advancements will help manufacturers stay competitive and meet the demands of the evolving metalworking industry.

Choosing the Right Upper Roll Forming Machine for Your Business

When choosing an upper roll forming machine for your business, consider your specific production needs, budget constraints, and available space. It's important to select a machine that is reliable, efficient, and capable of meeting your current and future manufacturing requirements.

Quote Inquiry

Contact us!