Table of Contents

In the modern construction industry, purification board machines play an important role, especially in multiple fields such as industrial plants, public buildings, and purification engineering. The application of purification board machines is an important manifestation of the pursuit of efficiency, environmental protection, and energy conservation goals in the construction field. The purification board machine can produce sandwich panels with various combinations of core materials and board types, meeting diverse building needs.

The handmade glass magnesium rock wool sandwich panel produced by the purification board machine occupies an important position in the market with good sealing performance and high fire resistance levels. This type of sandwich panel effectively prevents moisture and moisture infiltration, improving the service life and safety of buildings. At the same time, a high fire rating can effectively prevent the spread of fire and ensure the safety of buildings and personnel in the event of a fire.

The flame-retardant paper honeycomb purification board produced by the purification board machine is widely used in strict purification engineering fields such as electronics and food. The composite board composed of colored coated board, stainless steel, and other materials has unique dust-proof, anti-static, antibacterial, and other effects, providing a strong guarantee for purifying the environment.

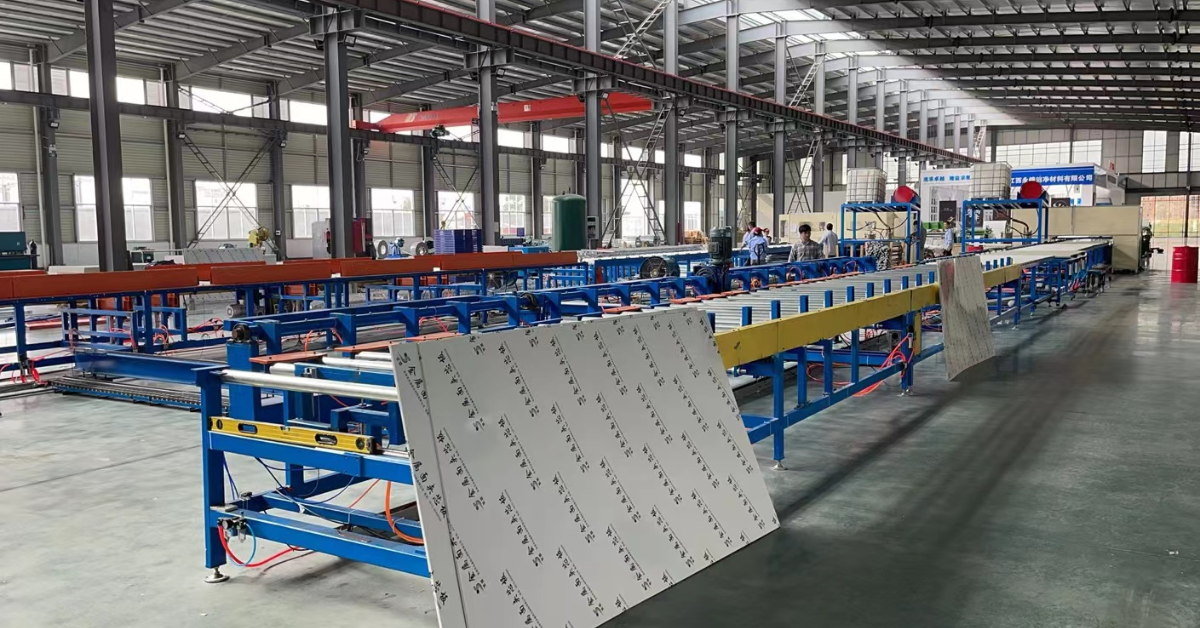

In the production process, the purification board machine adopts advanced technologies such as CNC servo, frequency conversion vector, and hydraulic control, ensuring fully automatic production and improving the operational efficiency of the entire production line. The operation of the purification board machine is simple, and automatic production can be achieved by integrating CNC technology with the power computer. Only relevant parameters need to be inputted.

In addition, the automation level of the purification board machine has been improved, effectively reducing labor costs. The entire production line only requires a few operators to complete production, while the efficient production speed significantly reduces production management and personnel costs.

At the same time, the technical performance indicators of the purification board machine have reached the international advanced level, providing customers with better quality choices at a better price and performance ratio.