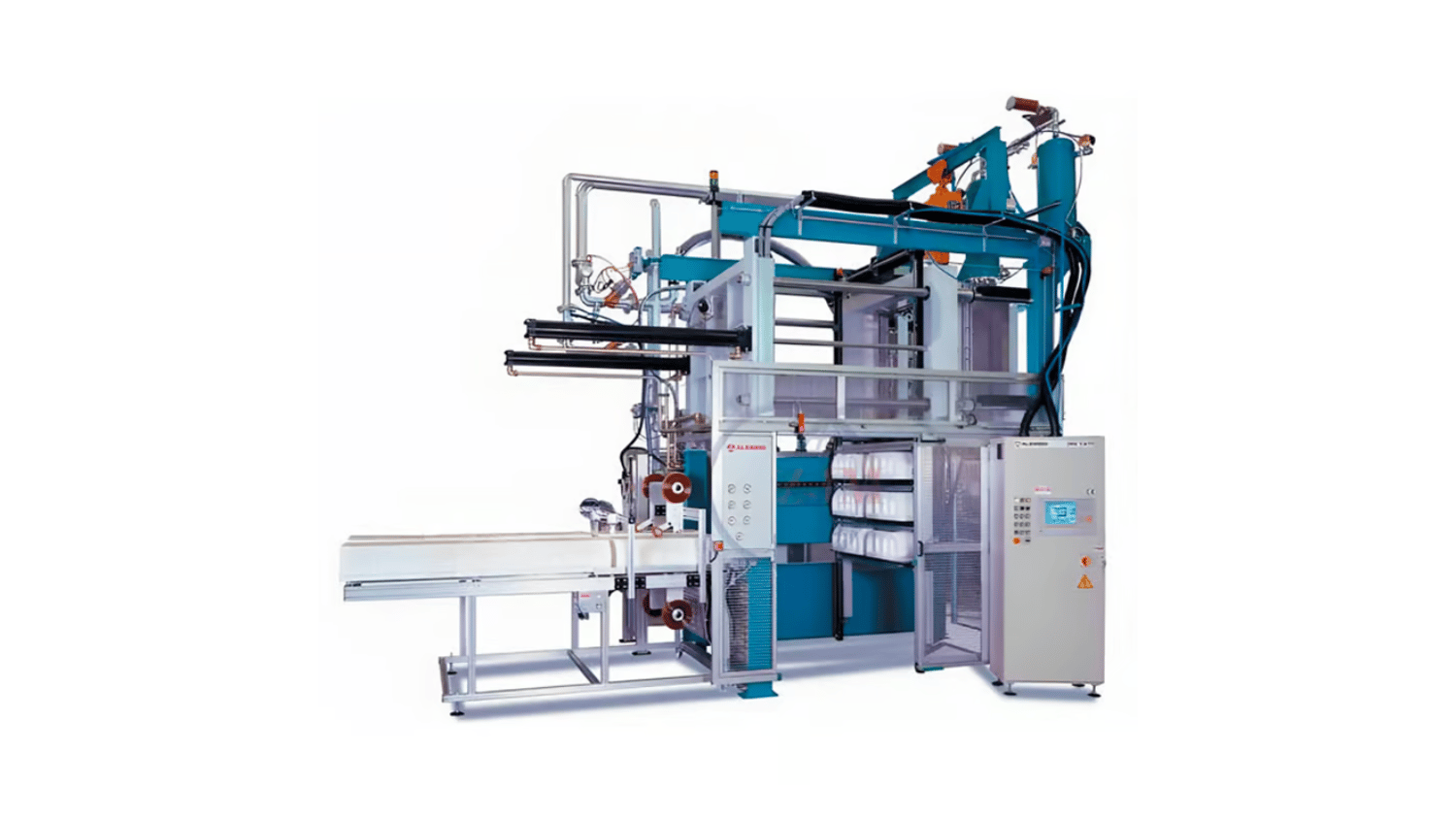

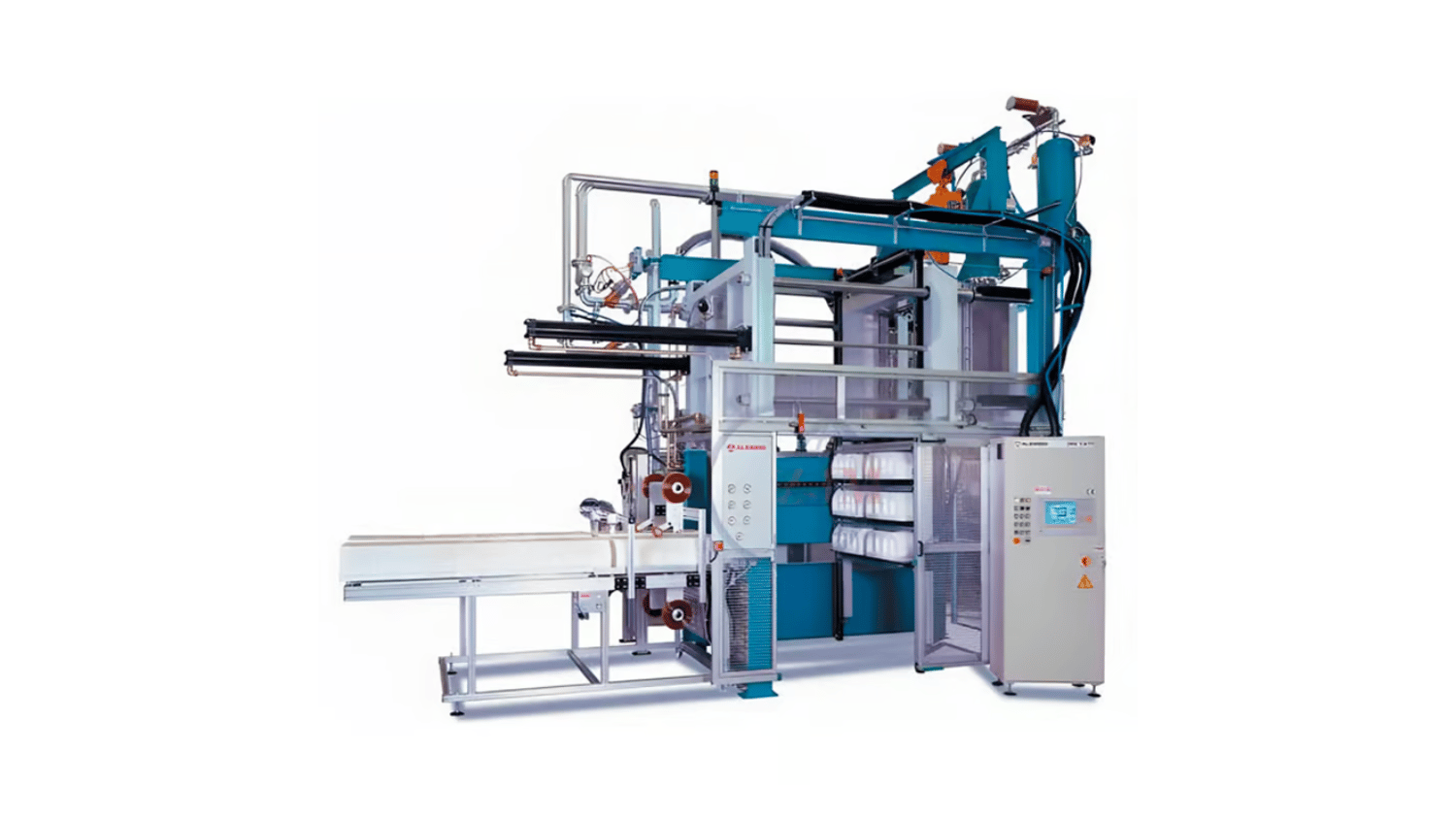

Introduction

If you want to stay competitive in the foam industry and save money on your energy bills, investing in a

High Efficiency & Energy Saving EPS Shape Molding Machine is a wise decision. This article will shed light on the different advantages of this cutting-edge device, from its ability to boost your productivity and lower your costs to its positive impact on the environment.

1. Enhanced Productivity

With a high efficiency & energy saving EPS shape molding machine, you can produce more foam shapes in less time, thanks to its advanced technology that streamlines the manufacturing process. This machine uses less energy and pumps out shapes faster than traditional molding machines, allowing you to increase your output and meet tight deadlines.

2. Energy Savings

By using a high efficiency & energy saving EPS shape molding machine, you'll notice a significant drop in your energy costs over time. This is due to the fact that these machines use less power to produce the same amount of foam products, making them an energy-efficient and cost-effective option for business owners.

3. Reduced Waste

The automated system of a high efficiency & energy saving EPS shape molding machine reduces the amount of foam waste produced during the manufacturing process. It uses precision technology to optimize foam production, which results in fewer irregular shapes and less material wasted.

4. Maximum Precision

A high efficiency & energy saving EPS shape molding machine uses advanced software and cutting-edge equipment to ensure complete and efficient foam molding. This means you can count on maximum precision and consistency, no matter what type of foam shapes you want to produce.

5. Increased Safety

High efficiency & energy saving EPS shape molding machines are designed with safety in mind. They have advanced features such as automatic alarms and shut-off systems that detect any malfunctions or overheating, ensuring the safety of operators and preventing accidents.

6. Customized Solutions

With a high efficiency & energy saving EPS shape molding machine, you can create a wide range of customized foam shapes, from simple blocks to complex geometrical structures. You can easily adjust the settings and parameters of the machine to suit your specific needs, giving you more flexibility and versatility in your production processes.

7. Reduced Maintenance

These machines are designed to require minimal maintenance, making them a low-maintenance investment in the long run. With fewer moving parts and simplified operating systems, high efficiency & energy saving EPS shape molding machines don't require regular maintenance, resulting in lower operating costs and increased productivity.

8. Investment Return

Investing in a high efficiency & energy saving EPS shape molding machine is a smart financial decision for your business. The cost savings from reduced energy usage and streamlined production processes will quickly pay for the initial investment, resulting in a significant return on investment over time.

9. Positive Environmental Impact

Using a high efficiency & energy saving EPS shape molding machine can have a positive impact on the environment by reducing your carbon footprint and negative impact on the planet. These machines produce less waste, use less energy, and are designed to minimize environmental damage.

10. Customer Satisfaction

With a high efficiency & energy saving EPS shape molding machine, you can produce high-quality foam shapes that meet the demands and expectations of your customers. This translates to increased customer satisfaction, which can lead to repeat business and a growing reputation in the industry.

High Efficiency & Energy Saving EPS Shape Molding Machine, Enhanced Productivity, Energy Savings, Reduced Waste, Maximum Precision, Increased Safety, Customized Solutions, Reduced Maintenance, Investment Return, Positive Environmental Impact, Customer Satisfaction

Why High Efficiency & Energy Saving EPS Shape Molding Machine is the Smart Choice

Discover the benefits of a High Efficiency & Energy Saving EPS Shape Molding Machine: Enhanced productivity, Energy savings, Reduced waste, Maximum precision, Increased safety, Customized solutions, Reduced maintenance, Investment return, Positive environmental impact, and Customer satisfaction.

Quote Inquiry

If you have any questions, please let us know asap!